Common Inspection Methods to Detect Failures in Hydraulic Punching Machines

Hydraulic punching machines are commonly used in many workshops, especially for metal fabrication. Generally, the machines possess considerable force and precision to assist owners and workers in completing production faster and with less manual labor. However, like all equipment, they also require proper care and regular upkeep to run smoothly.

Whether you’re running the machine or supplying the equipment, being able to spot early warning signs of trouble can save you time, money, and a whole lot of hassle later on. Let’s examine some useful, everyday inspection methods that can help prevent bigger problems later.

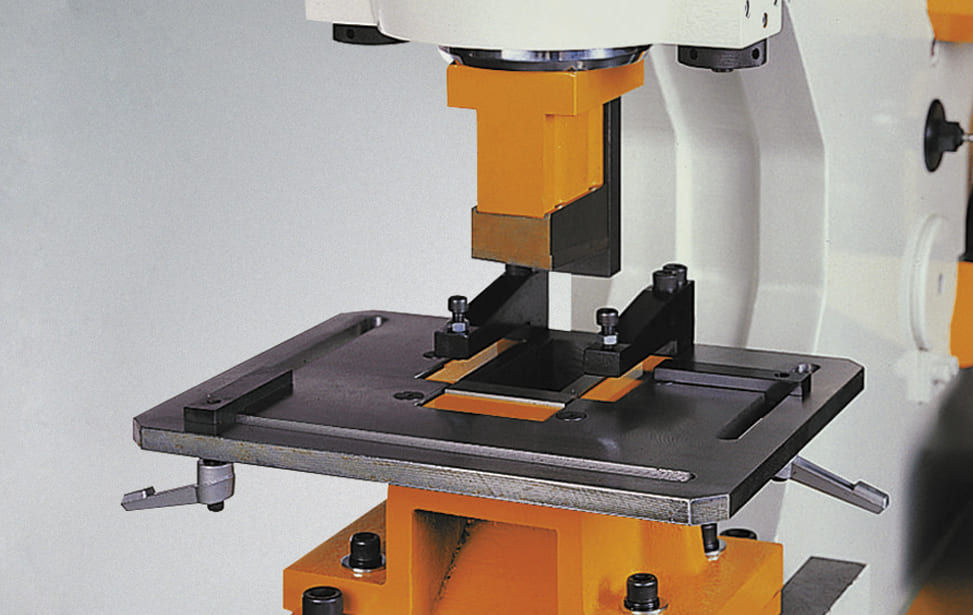

1. Start with a Simple Visual Check

A good old-fashioned visual inspection is often the easiest and most effective place to start. Take a few minutes to walk around the machine and check for anything unusual—leaking hydraulic fluid, cracks, rust, or loose bolts. If something looks off, it probably is. Pay attention to tool alignment and general wear and tear on the punching head, too.

It’s a quick habit that can catch minor problems before they escalate.

2. Monitor the hydraulic fluid

Hydraulic fluid is critical to the operation of these machines. It powers the movement and pressure required to punch through tough metals, which is why it is essential to check the hydraulic fluid. This check can help identify low oil levels, low oil quality, contamination from water or metal shavings, or other problems.

A one-time regular oil check, either visually or with a fluid testing kit, is a great way to stay on top of any problems and avoid sudden breakdowns.

3. Check System Pressure

If your machine is not punching like it used to, the pressure could be the issue. During usage, pressure gauges monitor operating levels and conditions to help identify the pressure issues that may be concealed while the machine is in operation. Generally, drops in system pressure(should include resting pressure vs. active pressure) can indicate clogged filters, failed pumps, internal leaks, and other mechanisms that could reduce an otherwise poorly functioning machine. Fixing these items early can keep your machine creating maximum work.

4. Be Aware of Unusual Sounds or Vibrations

Machines convey signals – you simply have to know how to listen for them. If your hydraulic punching machine is making weird noises (i.e. hissing, grinding or knocking), this could indicate something is wrong with it. Alternatively, if it experiences excessive vibration, this is another warning sign, potentially indicating misalignment or a loose part. If it does not sound right or feel right, don’t dismiss it.

5. Use a Temperature Check

Hydraulic systems can often overheat too much, too. If specific parts of the machine are overheating unusually fast, that could be a cause for concern. Using infrared thermometers and thermal imaging cameras allows you to locate overheated areas in the motor, hydraulic hoses, or control panel. Finding hot spots early can help prevent more serious problems later on.

6. Check the Tooling for Wear

The punching tool and die take a lot of stress during operation. Over time, they naturally wear out. Regular inspection for dull edges, chips, or burrs helps keep the punch clean and accurate. Swapping out worn tooling not only improves results, it also protects the rest of the machine from damage.

7. Run System Diagnostics

Many advanced hydraulic punching machines can now offer a digital display or programmable controller. Like the hydraulic punching machines, they can display error messages, fault codes, or past issues from a list. By running diagnostic tests periodically, you can uncover issues with sensors, alignment, or the control system that you may have missed otherwise.

8. Stick to a Maintenance Schedule

Finally, always follow a regular maintenance plan. Clean the machine on a regular basis, lubricate moving parts, replace filters, etc. Most machine makers have a service schedule, and if you follow it, it will make a difference.

If you are dealing with a reputable workshop equipment supplier in UAE, you will also be able to get maintenance support, spare parts, and professional expertise that suits your machine manufacturer model.

Hydraulic punching machines are powerful, reliable tools—but only when they’re properly looked after. By using a mix of visual checks, fluid testing, pressure monitoring, and system diagnostics, you can catch small problems before they turn into big ones.

And if you’re running a busy metal workshop or managing equipment across multiple sites, partnering with an experienced workshop equipment provider in UAE can give you peace of mind and expert support when you need it most.

At the end of the day, a little maintenance goes a long way in keeping your machines (and your team) productive and safe.

To read more, click here : Single-Phase vs. Three-Phase Industrial Vacuum Cleaners: Key Differences Explained