How to Calculate Production Capacity with Different Hydraulic Punching Machine Models

For any manufacturing or fabrication company, especially in the bustling industrial environment of the UAE, the ability to recognize and optimize a company’s production capacity is a direct route to profitability and expansion. In production and fabrication environments, a hydraulic punching machine is often at work, punching a variety of shapes into metal. Although these machines are all capable of punching, they do vary quite a bit in the different models and characteristics, resulting in large variations in production capacity. Knowing how to accurately count the production output of your machine is the key to managing your projects effectively, as well as providing the proper timeframe and workflow for making informed equipment decisions.

This guide will give the basic principles that affect machine capacity, show how to practically calculate them, and help you to understand how different models of hydraulic punching machines relate to your particular workflow and application. The focus is on using your machine efficiently to meet your business objectives.

The Foundation: Understanding Capacity

Before we get into numbers, we must clarify what production capacity is. In this case, it is the maximum number of punches or finished parts a machine can produce over a given period (time frame that could be an hour, or a shift, or whatever). It’s a measure that is much more complex than it looks.

* Theoretical Capacity – This is the maximum the machine can run at max-out performance without any interruptions whatsoever. It is a good reference point for making comparisons, but it rarely matches what would happen in an actual busy shop.

* Actual Capacity – this number will take into consideration the necessary lost time, such as the following downtime for material handling & loading, tool changing time, maintenance time, and off time for the operator. This is the number that matters when you are planning a business.

The main takeaway is that even in the family of hydraulic punching machines, there can be significant differences in actual capacity depending on the model of the machine and the features it has. And, to do a proper calculation, you have to really know what your machine & operational needs are for choosing capacity numbers.

Core Specifications That Dictate Output

The production capacity of a hydraulic punching machine is primarily determined by its core specifications. These are the details you should always consider:

1. Tonnage (Punching Force): This is the most critical factor. Tonnage dictates the maximum force the machine can apply, which in turn determines the thickness of material it can punch and the maximum hole diameter it can create. A higher-tonnage model is suited for heavy-duty jobs on thicker steel plates, while a lower-tonnage machine may offer a faster stroke rate for thinner materials. Matching the tonnage to your typical projects is crucial for efficiency.

2. Stroke Rate (Cycles Per Minute): This is the most direct measure of a machine’s speed. It’s the number of times the ram can move up and down to perform a punch in one minute. For simple, repetitive tasks that require no tooling changes, a higher stroke rate directly translates to higher theoretical output.

3. Throat Depth: This dimension, the distance from the machine’s frame to the center of the punch, dictates the size of the workpiece that can be processed. A deeper throat allows for punching holes farther from the edge of a large sheet, expanding the range of jobs the machine can handle. While it doesn’t directly affect the speed of a single punch, it increases overall capacity by allowing a broader scope of work.

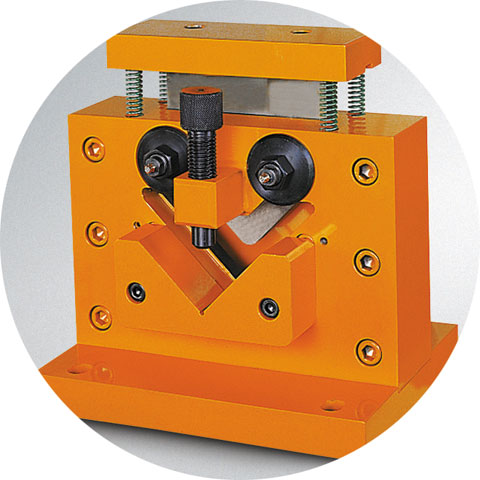

4. Tooling and Configuration: This is a major differentiator between hydraulic punching machine models. A basic single-station machine requires a manual tool change for every different hole size. However, more advanced models can be equipped with quick-change tooling systems or even multi-tool holders. These features drastically reduce the “non-punching” time required for setup, which in turn elevates the actual production capacity.

A Practical Capacity Calculation

Let’s apply these factors with a simple calculation that works for any hydraulic punching machine, regardless of its configuration.

Actual Production Rate = (60 minutes / (Punching Time per part + Non-Punching Time per part))

* Punching Time per part: This is calculated by dividing the number of punches per part by the machine’s stroke rate.

* Non-Punching Time per part: This is where the model’s features are most apparent. For a single-station manual machine, this time is significant as it includes physically feeding the material and manually changing tools. For a model with quick-change tooling or a multi-tool holder, this time is reduced to just a few seconds, dramatically increasing the overall output.

Example:

* Machine A (Basic Model): Has a stroke rate of 40 punches per minute. A part requires one punch, but it takes 15 seconds for the operator to load the material.

Actual Rate = 60 / (1.5 seconds punching + 15 seconds handling) = ~218 parts per hour.

* Machine B (Advanced Model with Quick-Change Tooling): Has the same stroke rate of 40 punches per minute, but a part requires 3 punches and it takes only 5 seconds to load the material.

Actual Rate = 60 / (4.5 seconds punching + 5 seconds handling) = ~381 parts per hour.

This simple illustration demonstrates how the configuration of a hydraulic punching machine—not just its brute force—is a critical component of its true productive capacity.

Making a Strategic Decision

Understanding these calculations is vital for any business. The biggest, most powerful hydraulic punching machine isn’t always the best choice. The right machine for your workshop in the UAE is one that perfectly matches your typical workload, material types, and production volume.

Prior to buying, get expert guidance from a trusted supplier of workshop tools in UAE. They can help you analyze your specific needs and recommend a machine that offers the optimal blend of power, speed, and efficiency for your operation. A well-chosen hydraulic punching machine is a powerful asset that drives profitability and positions your business for success in a competitive market.

To read more, click here: Hydraulic Tapping Machines: Why They’re Still Essential for Heavy-Duty Threading