How AI and Automation Are Transforming the Way We Choose Workshop Equipment

The landscape of the workshop is changing quickly. No longer is it enough for a machine to be robust. Now, shops in the UAE and across the globe are seeking smarter, faster, and more efficient equipment. Thanks to AI and automation, that’s exactly what’s becoming possible.

If you’re in the market for new machinery or just keeping an eye on industry trends, you’ll quickly notice one thing: workshop equipment is getting a major tech upgrade. And for anyone choosing a workshop equipment supplier in the UAE, the conversation has shifted from “how tough is it?” to “how smart is it?”

Smarter Machines for Smarter Work

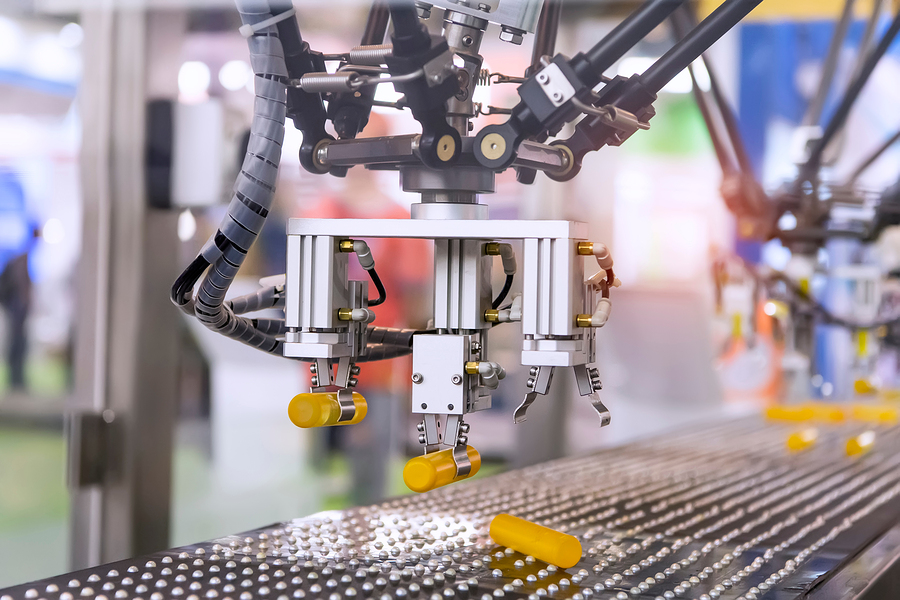

Imagine a lathe machine that can adjust itself depending on the type of material being worked on. Or a tapping machine that senses the right torque to avoid damaging your part. These aren’t science fiction—they’re real, AI-powered features that are quickly becoming the standard.

In a busy workshop, this kind of automation saves time, reduces human error, and makes sure every cut or weld is precise. It also frees up your team to focus on more skilled tasks instead of constantly monitoring or correcting the machines.

Automation Is Boosting Productivity Everywhere

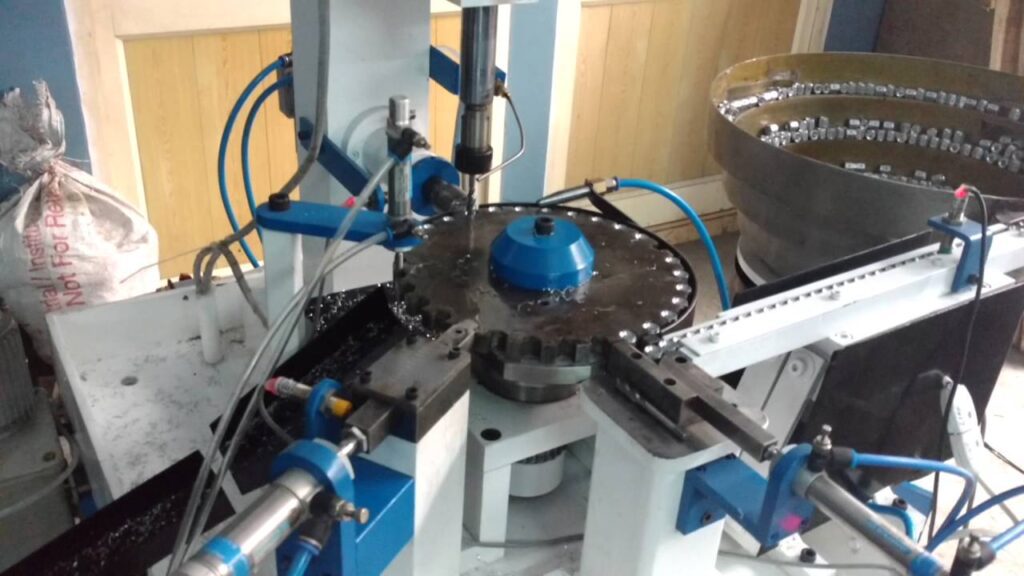

Today’s workshops don’t just want to get the job done—they want to do it faster and better. That’s where automation comes in. Whether you’re working with CNC roller machines, ironworker machines, or more traditional tools, automation helps take care of repetitive tasks with minimal supervision.

For example, a modern ironworker machine can now punch, shear, and notch all in one go, without needing manual setup for each step. That means quicker turnaround times, fewer errors, and better consistency across the board.

Preventing Problems Before They Happen

A second revolutionary change is how artificial intelligence is helping us maintain our equipment. Nowadays, many machines come equipped with onboard (or aftermarket) sensors that can track the performance of the machine itself. If something isn’t right—a motor is overheating or a bearing is wearing unnecessarily—you get a heads up before you lose machine time.

This is only going to lead to more predictive maintenance, leading to better performance of machines and prevention of costly breakdowns. It is just one more reason that investing in AI-ready equipment from a quality workshop equipment supplier is a logical business choice.

Clean, Safe, and Smarter Workspaces

And let’s not forget about another important aspect of any workshop: cleanliness and safety. Some of the modern industrial vacuum cleaners now include smart sensors that adapt to the surface or type of debris, and some actually navigate pre-programmed cleaning routes, so you can keep dust at bay with less effort, keeping your workspace clean and free of debris.

Cleaner environments equal fewer health hazards, safer working conditions, and higher-performing teams. This is yet another area where AI and automation are stepping up in ways we may have never suspected.

Flexibility Is the New Standard

Workshops today are handling more custom jobs than ever before. That means machines need to be flexible—able to switch between materials, sizes, and tasks without slowing down.

Take CNC roller machines, for example. Instead of resetting everything manually between projects, these machines adjust automatically. That means less setup time and more output, even for complex or one-off jobs.

With automation built in, your workshop becomes more adaptable to changing client needs—something every business values.

What to Look for in a Workshop Equipment Supplier in UAE

If you’re thinking of upgrading or expanding your workshop, choosing the right supplier makes all the difference. A great workshop equipment supplier in UAE doesn’t just sell machines—they understand your goals and guide you to the right tools for the job.

Here’s what you should expect from a top supplier:

- Equipment that’s ready for automation and AI integration

- Expert advice based on your specific industry needs

- Support and training, especially for smart or connected machines

- A strong network for spare parts, upgrades, and after-sales service

Some of the best suppliers in the UAE also work closely with major industries like oil and gas, marine, and construction. They know the challenges you face and can recommend tools that keep your operations running smoothly and efficiently.

Getting Ready for the Future

The workshop of today looks very different from what it did a few years ago—and it’s only going to keep changing. Whether you’re in fabrication, metalworking, or manufacturing, staying competitive means being open to smarter solutions.

AI and automation have moved beyond being ‘nice to have’ features—they’re quickly becoming essentials. Machines that think, learn, and adapt aren’t just making life easier. They’re helping businesses reduce costs, boost quality, and grow faster.

Final Thoughts

So, where do you start? Look for a trusted industrial equipment supplier who understands these changes and offers the tools and support you need. Whether it’s lathe machines, tapping machines, or even industrial vacuum cleaners, make sure your next purchase is a step toward a smarter, more efficient workshop.

In a world where technology is evolving every day, investing in smarter equipment is one of the best ways to future-proof your business, without waiting for the future to arrive.

To read more, click here: 5 Key Features That Make CNC Plate Rolling Machines Essential in Modern Manufacturing