Understanding Stroke Length and Its Impact on Punching Performance

In metal fabrication and sheet processing, punching performance is crucial for productivity, accuracy, and operational efficiency. One frequently overlooked yet highly influential factor is stroke length. Whether you’re operating advanced hydraulic systems or evaluating new equipment for your factory, understanding stroke length helps you make smarter decisions, especially in the UAE’s competitive manufacturing market.

As demand for precision manufacturing increases across the UAE, industries are investing in high-performance machines, including hydraulic punching solutions. Stroke length has a significant impact on machine speed, operational accuracy, tool wear, and energy efficiency, making it a crucial criterion for selecting industrial machines in the UAE.

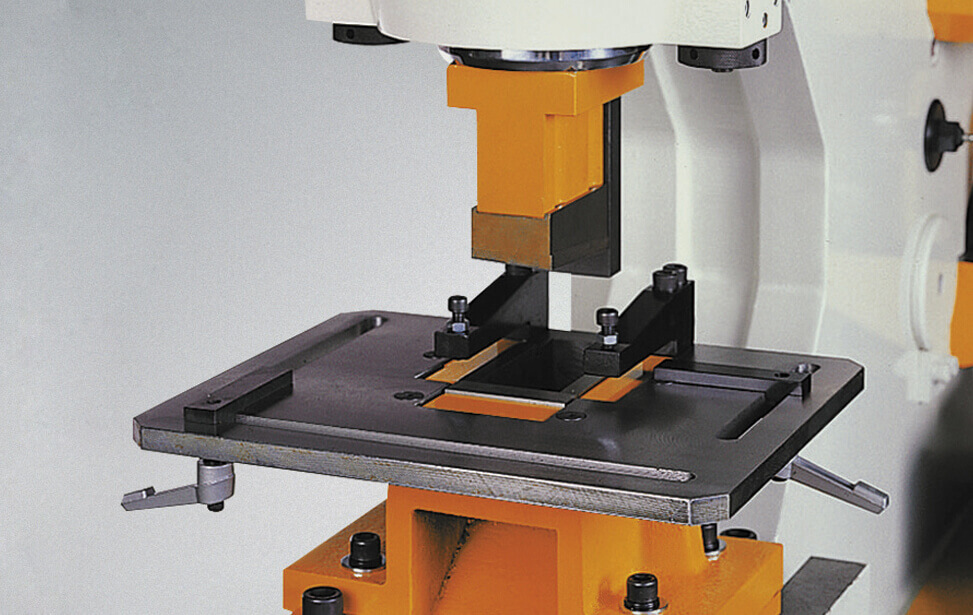

What Is Stroke Length in Punching Machines?

Stroke length represents the complete vertical travel of the punching ram through a single operating cycle, descending from its highest point to the lowest and then returning. This action influences both penetration performance and retraction efficiency.

In hydraulic punching machines, stroke length can often be adjusted based on material thickness, tooling requirements, and production needs. This adjustability is why hydraulic punching machines remain popular across sectors like construction, automotive, electrical enclosures, and metal fabrication throughout the UAE.

Why Stroke Length Matters

Stroke length has direct, measurable effects on punching performance. Choosing the appropriate stroke length enhances output quality while minimizing machine wear and operational costs.

Punching Speed and Productivity

Shorter stroke lengths generally result in quicker cycle times. When the ram moves only the required distance, the machine can perform more punches per minute. In high-volume UAE production settings, this efficiency results in substantial reductions in time and operating costs.

Manufacturers fine-tune stroke length to achieve an optimal balance of speed and precision, particularly when processing thin materials or repetitive punch patterns. Achieving this balance is what distinguishes strong operations from exceptional ones.

Energy Efficiency

Longer strokes draw more hydraulic power and increase overall energy consumption. In the UAE’s sustainability-driven industrial landscape, optimizing stroke length supports energy savings without affecting machine performance.

Hydraulic systems with programmable stroke control let operators minimize unnecessary movement. This makes modern hydraulic punching machines an intelligent choice for energy-conscious UAE manufacturers looking to reduce overhead.

Tooling and Machine Life

Excessive stroke length puts additional stress on tooling and mechanical components. Over time, this results in premature wear, increased maintenance expenses, and unplanned downtime. Optimizing stroke adjustment significantly extends the life of punches, dies, and the machine itself. For factories investing in industrial machinery, long-term reliability is essential. At Rockwood Workshop Machines, we know that the right stroke length delivers stronger returns on investment while keeping production lines operating efficiently.

Stroke Length and Material Thickness

Material thickness and hardness directly influence stroke settings. Heavier materials require longer strokes for clean penetration and slug removal, whereas thinner materials achieve better results with shorter, faster strokes.

UAE manufacturers often work with diverse metals, from aluminium to stainless steel. The flexibility offered by hydraulic punching machines allows operators to adapt stroke length to each job, ensuring consistent quality across applications. This versatility is what modern fabrication demands.

Precision and Accuracy in Punching

Stroke length also influences punching accuracy. Excessive stroke movement can cause vibration, misalignment, or inconsistent hole quality. Controlled stroke lengths improve stability during punching, delivering smoother edges and tighter dimensional control.

This precision level is especially important in industries like electrical panel manufacturing and architectural metalwork, both rapidly expanding in the UAE. Quality industrial machinery delivers this precision consistently, punch after punch.

Automation and Stroke Control

Modern hydraulic punching machines often feature CNC controls and programmable stroke settings. This automation allows operators to store optimized stroke parameters for different materials and jobs, improving repeatability and reducing human error.

In the UAE, as smart manufacturing and Industry 4.0 adoption continue to advance, these advanced capabilities are increasingly viewed as standard requirements rather than premium additions. Automated stroke control improves both efficiency and output quality, making it essential for modern hydraulic punching operations.

Finding the Right Punching Machine

Stroke length capability is an important factor to assess when selecting punching equipment. Equipment with adjustable or programmable stroke options delivers greater versatility and improved efficiency.

Rockwood Workshop Machines recommends hydraulic punching solutions because of their flexibility, reliability, and ability to handle varying stroke requirements. For UAE businesses, investing in the right machine means improved competitiveness in both local and international markets. The decision you make today affects your productivity for years to come.

Conclusion

Knowing stroke length and its effect on punching performance is essential for manufacturers aiming to maximize operational efficiency. From productivity and energy efficiency to tooling life and precision, stroke length influences nearly every aspect of punching performance.

As the UAE’s industrial sector expands, the requirement for advanced, reliable, and efficient equipment is expected to increase. By choosing modern hydraulic punching machines with optimized stroke control, businesses can ensure high-quality output, reduced operating costs, and long-term success in the UAE’s evolving industrial landscape. The right equipment, properly configured, provides a strong competitive edge in today’s marketplace.

To read more blogs, click here : Metal Fabrication Industrial Machinery Trends in Dubai for 2026