Optimizing Cutting Parameters for Maximum Efficiency on Vertical Lathe Machines

Vertical lathe machines in UAE are used to shape and process cylindrical workpieces in the manufacturing and metalworking industries. These machines are commonly used across various industries, such as aerospace and automotive. For businesses utilizing lathe machines, fine-tuning cutting parameters is important for improving productivity, cutting costs, and delivering high-quality finishes. This blog deals with effective practices for optimizing cutting parameters on vertical lathe machines and emphasizes the importance of selecting the right workshop tools in UAE.

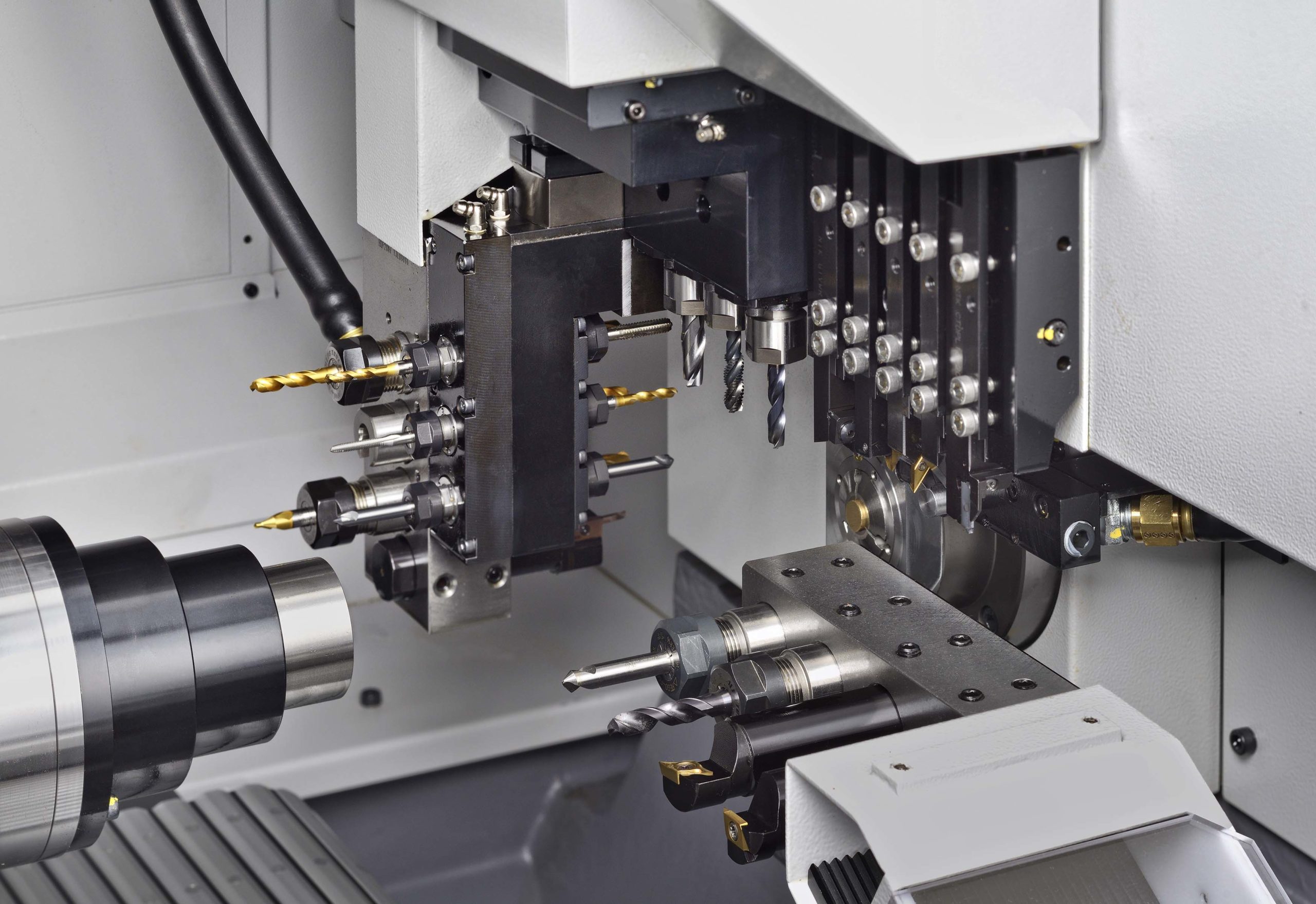

Vertical Lathe Machines in UAE: What Are They?

Vertical lathes simplify processes for cutting large materials and provide better chip removal than standard horizontal lathe machines. Because of their exceptional support and stability, vertical lathes are the best tool for machining big, heavy objects. Compared to traditional horizontal lathes, vertical lathe machines offer improved chip removal and simplify operations for machining large materials.

Major Cutting Parameters to Consider

To achieve optimal results with vertical lathes, it’s essential to consider the following major cutting parameters:

1. Cutting Speed: This is the speed at which the cutting tool goes into the workpiece. The standard units used to measure this number are surface feet per minute (SFM) or meters per minute (MPM). The ideal cutting speed varies depending on the material being machined, the type of tool used, and the quality of finish desired.

2. Feed Rate: It is the linear distance the cutting tool covers in one complete rotation of the workpiece. Inches per revolution (IPR) or millimeters per revolution (MMPR) is the standard unit used to measure the feed rate. The ideal cutting speed varies depending on the material being machined, the type of tool used, and the quality of finish desired.

3. Depth of Cut: This is the parameter used to measure the cutting tool’s penetration depth into the workpiece. The rate at which material is removed and the total productivity of the machining process are both greatly affected by the depth of cut.

4. Tool Geometry: The cutting tool’s design influences its performance. The rake angle, clearance angle, and nose radius of the cutting tool are the major factors that should be considered while selecting the best tool for your specific application.

Optimizing Cutting Speed

On vertical lathe machines, choosing the right cutting speed is essential to getting the greatest results. Here are some guidelines:

1. Material Properties: Different materials have different levels of hardness, which impacts the optimal cutting speed. While stronger materials like stainless steel require slower cutting speeds to avoid tool damage, softer materials like aluminum can be machined at greater speeds.

2. Tool Material: The kind of cutting tool material, like high-speed steel (HSS), carbide, or ceramic, is also really important for how fast you can cut. Carbide tools can handle higher speeds due to their superior hardness, whereas HSS tools may need to be operated at lower speeds.

3. Monitoring Tool Wear: Regularly checking tool wear is critical. To achieve optimal performance and quality, tool wear might limit efficiency, necessitating modifications to cutting speeds. Implementing real-time monitoring systems can help assess tool health and make necessary adjustments instantly.

Fine-Tuning the Feed Rate

Achieving the balance between surface finish quality and productivity need to adjust the feed rate. Here’s how to optimize the feed rate on vertical lathes:

1. Material Considerations: The ideal feed rate is determined by the type of material, like cutting speed. Harder materials need slower feed rates to preserve a good finish and avoid tool wear, but softer materials can usually handle faster feed rates.

2. Desired Surface Finish: The quality of the surface finish you want will influence the feed rate. A smoother finish usually needs a slower feed rate, while roughing operations can benefit from higher rates without sacrificing quality.

3. Testing and Adjusting: Conducting test cuts to analyze results can help pinpoint the optimal feed rate for various applications. By testing various feed rates and analyzing the outcomes, operators can make choices that enhance both speed and quality in the machining process.

Depth of Cut: Key Considerations

The depth of cut is another important factor in enhancing efficiency on vertical lathes. Choosing the right depth can make an impact on productivity levels and material removal rates.

1. Increasing Depth for Roughing: During roughing operations, increasing the depth of the cut can significantly boost material removal rates. However, it’s important to consider the machine’s rigidity and the stability of the workpiece, as excessive depth can lead to vibrations and tool wear.

2. Shallow Cuts for Finishing: In finishing operations, shallower cuts are often preferable. This approach allows for better control over the surface finish and reduces the risk of tool deflection, which could affect the final product.

3. Monitoring Stability: Make sure the workpiece is intact and the machine is stable at all times. To prevent disruptions and maintain smooth operation, it might be necessary to modify the depth of the cut or other settings if vibrations become excessive.

The Significance of Tool Geometry

The choice of tool geometry plays a crucial role in optimizing vertical lathe performance. The quality of the machined surface, chip removal, and cutting efficiency are all controlled by the tool’s design.

1. Rake and Clearance Angles: The rake angle impacts how the tool engages with the material, while the clearance angle prevents the tool from dragging against the workpiece. By adjusting cutting angles, cutting performance can be improved.

2. Tool Shape: Different applications may necessitate unique tool shapes. For example, a rounded nose radius is used to improve surface smoothness, while a sharper nose is needed to make deeper cuts in hard materials.

3. Tool Coatings: For increased durability and performance, use coated tools. Coatings like TiN can significantly enhance tool performance by improving hardness, reducing friction, and extending tool life, leading to increased productivity and lower costs.

Optimizing cutting parameters on vertical lathes can significantly enhance efficiency, minimize expenses, and deliver superior machining quality. Focusing on important factors like cutting speed, feed rate, depth of cut, and tool geometry can help businesses greatly improve their operations.

Businesses invested in lathe machines and workshop tools can improve their efficiency and profitability by following these best practices. Continuous monitoring and modifications are necessary for businesses to remain competitive in the growing manufacturing industry. By implementing these optimization strategies, businesses can fully utilize the capabilities of their vertical lathes to produce the highest quality output.

To read more click here : The Importance of Quality Tooling in Hydraulic Punching Machines for Productivity