Portable Tapping Machines vs. Fixed Models: Which One Suits Your Fabrication Needs?

In present-day fabrication and manufacturing, efficiency and accuracy are essential factors. Whether running a small workshop or operating a large industrial facility, tapping machines are among the most important tools you will invest in for your workshop. These machines make internal threads in holes, which is closely followed in the assembly of most mechanical and structural parts.

As fabrication demands advance, one common question seems to come up regularly: Should I be looking for portable tapping machines or should I invest in fixed machines? Each type of machine has its benefits, and the best choice will depend on your projects, operational scale, and environment in which you are working. As more companies consider portable tapping machines, we can investigate the two more closely.

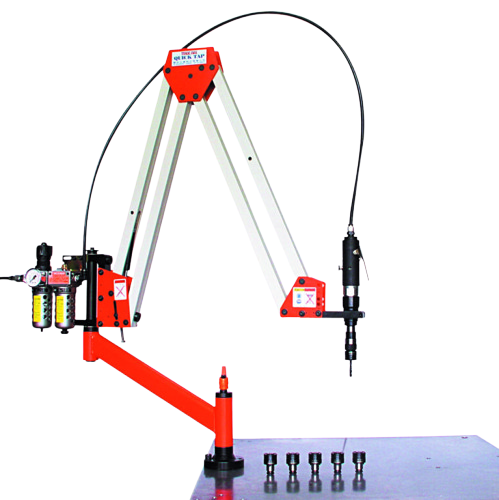

Portable Tapping Machines: Flexibility in Action

Portable tapping machines are all about mobility and convenience. Instead of bringing a heavy or awkward workpiece to a stationary machine, the tapping tool can process it directly in the position of the material. This design makes them especially useful in industries such as construction, shipbuilding, and maintenance, where job sites or work in place are common, and efficiency is important.

Their compact and user-friendly design minimizes downtime and makes handling easier. By avoiding having to reposition large items, portable models save time and labor. Many modern models have variable speeds, ergonomic features, and the capability to work with a variety of materials, including soft aluminum and hardened steel.

Key Advantages of Portable Machines

- Mobility: Perfect for workshops that handle oversized or immovable parts.

- Space-Saving: A great choice for smaller facilities because they don’t require a permanent setup.

- Versatility: Capable of tapping holes in different shapes, sizes, and materials.

- Cost-Effective: Typically involves a lower upfront investment compared to fixed machines.

Limitations to Consider

- Might not manage mass production as well as fixed machines.

- Less capacity and power than heavy-duty, industrial-grade machines.

For small to mid-sized businesses—or businesses dealing with projects a lot of times in a remote or varied environment—a portable tapping machine is a practical, cost-effective solution.

Fixed Tapping Machines: Power and Precision

At the other end of the spectrum are fixed tapping machines, built for stability, accuracy, and heavy-duty use. Installed permanently in workshops or production lines, these machines are engineered for high-volume applications where speed, consistency, and precision are top priorities.

Because of their solid, vibration-free construction, fixed machines produce uniform threads that meet the strict tolerances required in industries like automotive manufacturing, aerospace, and large-scale fabrication. Their ability to run continuously without compromising accuracy makes them crucial in standardized production environments.

Key Advantages of Fixed Machines

- High Output: Built for uninterrupted performance and high-capacity batch processing.

- Superior Precision: Deliver consistent results across thousands of identical parts.

- Durability: Built to withstand long-term use in demanding industrial environments.

- Automation Options: Many models now feature advanced automation, reducing manual intervention and further increasing productivity.

Limitations to Consider

- Require significant floor area, potentially unsuitable for smaller workshops.

- Initial investment tends to be higher.

- Moving large or heavy workpieces to the machine can be time-consuming and costly.

For businesses focused on mass production and high-quality threading, fixed tapping machines remain the gold standard.

Choosing the Right Option

When deciding between portable and fixed tapping machines, it’s important to assess your specific requirements rather than relying on a one-size-fits-all solution. Here are some key factors to guide your decision:

Workpiece Size and Type

- Large, bulky materials are much easier to handle with portable machines.

- Smaller, standardized parts align better with fixed setups.

Production Volume

- Fixed machines are the clear winner when it comes to uninterrupted, high-volume production.

- Portable options are better for smaller batches or one-off projects.

Work Environment

- Portable machines thrive in diverse or remote locations.

- Fixed machines are better suited for controlled workshop environments.

Budget

- Portable machines typically involve a lower investment and reduce handling costs.

- Fixed models cost more upfront but deliver long-term efficiency for high-output facilities.

Striking the Balance

In actuality, it is not always choosing one over the other. Many workshops discover that the best solution is to use both. For example, a fixed tapping machine would tap a standardized part in a high-volume production environment, while a portable tapping machine would be employed for site work or a project with unique parts at a lower volume.

This strategy provides flexibility without losing consistency and productivity. An established reputable industrial equipment supplier in UAE might suggest distributing a heavy-duty fixed tapping machine for workshop use and a portable machine for field use, providing businesses with the ability to quickly adapt to a project’s change in requirements while maximizing their return on assets.

Why the Right Supplier Matters

Choosing the best tapping machine is just part of the process, as finding a reliable distributor is equally important. A company that deals with industrial equipment may have high-quality machines, but it will also offer support after the sale, spare parts, and maintenance to keep your machines up and running.

Even a supplier can assist in deciding on portable or fixed, based on your production volume, workshop layout, and budget. Working with an experienced supplier is especially helpful for companies that are just now looking at portable tapping machines in UAE or for any company upgrading from their last set of workshop tools.

Conclusion

Both portable and fixed tapping machines serve a crucial function in modern fabrication. Portable models shine when it comes to flexibility, mobility, and cost savings, making them invaluable for workshops handling large or diverse materials. Fixed machines, on the other hand, deliver unmatched power, consistency, and productivity—qualities that are critical in large-scale, high-output facilities.

When it comes down to it, the decision ultimately depends on your projects, production capacity, and long-term goals. For many businesses, the best option is to invest in both types, which will have you prepared in every situation. With a dependable industrial equipment supplier in UAE, you can have all of the possible options, while making sure your operations run smoothly, stay competitive, and get ready for your future needs.

To read more blogs, click here: 3 Space-Saving Advantages of Choosing Compact K Series Models