- Drilling and Tool Grinding Machine

- Foam Gasket Forming Machines

- Vacuum cleaners

- Vertical lathes

- Carbide Application Equipment

- Workshop Machinery

- Tapping Machine

- Hydraulic Ironworker

- CNC Drilling and Milling machine

- Drilling and Milling machine

- Bench Drilling Machine

- Pillar type drilling machine

- CNC Lathes

- Sheet Metal Angle Notching Machine

- CNC Precision 4-high Roller Leveling Machine

- Fastener Insertion Machine

- Hydraulic Punching Machine

- Special Offer

- Radial Drilling Machines

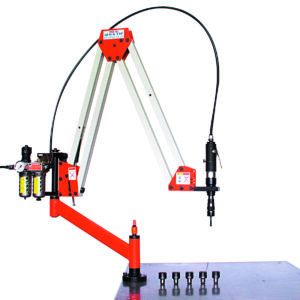

Electric Tapping Machine Type IMT

Electric tapping machines, like the Type IMT, offer a powerful and versatile solution for high-volume thread tapping operations. Designed for precision and efficiency, this industrial-grade tapping machine from [Your Company Name] enables manufacturers to achieve exceptional results in creating internal threads across a range of materials.

Key Features of the IMT:

– Powerful Electric Motor: Provides reliable performance for continuous tapping, handling materials from M3 to M24 (metric thread sizes).

– Variable Speed Control: Allows operators to adjust the tapping speed based on material and thread size, optimizing both thread quality and production times.

– Extensive Working Range: With a working range of Rmax 1900mm (maximum) to Rmin 200mm (minimum), the IMT is highly versatile, accommodating a wide variety of tapping needs.

– Durable Construction: Built with a solid machine frame and high-quality components, the IMT ensures long-lasting performance and minimal maintenance.

– Multiple Spindle Options: Choose from a range of tapping spindles (M3 – M12, M3 – M16, or M3 – M24) to suit your specific application requirements.

– User-Friendly Design: The intuitive control panel and ergonomic layout enhance operator comfort and reduce training time.

– Safety Focus: Includes overload protection and an emergency stop function for added operator safety.

Benefits of the IMT:

– Increased Production Efficiency: The high-torque motor and variable speed control facilitate faster tapping cycles compared to manual or pneumatic machines.

– Enhanced Thread Quality: Adjustable speed settings ensure consistent, accurate threads, minimizing rework and ensuring high-quality production.

– Reduced Operator Fatigue: The ergonomic design reduces strain, enhancing productivity during long shifts.

– Versatility for Various Applications: The IMT’s broad working range and multiple spindle options make it suitable for diverse industries, including automotive, aerospace, and general metalworking.

– Cost-Effective Operation: The electric motor operates more cost-effectively compared to pneumatic tapping machines.

Ideal for:

– High-volume production lines in industries like automotive, aerospace, and general metalworking.

– Applications needing consistent and high-quality internal threads.

– Workshops and factories aiming to improve tapping efficiency and reduce production times.

The IMT Electric Tapping Machine is a reliable solution for tapping machines in UAE, offering enhanced versatility and lower operating costs compared to pneumatic alternatives.

Product ID: IMT-Series

Powered by electricity, this machine utilizes the TRADEMAX self-developed induction motor and offers a working range of up to 1900mm with a tapping capacity of M3 to M24. The machine operates more quietly than pneumatic versions and features an adjustable motor speed control. The movable arm design simplifies operation and offers greater convenience. Additional tapping attachments and accessories can be purchased for multi-functional use based on working conditions.

Product Character

| Model | IMT Series | ||

| Spindle | M3 – M12 | M3 – M16 | M3 – M24 |

| Speed (rpm)(rpm) | 0-400 | 0-300 | 0-200 / 0-60 |

| Work Range | Rmax 1900mm Rmin 200 mm | ||

| Voltage | 220V, Single-PHASE | ||

| Electric Motor | 0.55 kw | ||

| N.W/G.W (kg) | 23.5 / 28.5 | 26.5 / 31.5 | 37.5 / 42.5 |

Standard Accessories

●Electric tapping spindle

●Parallel arm

●Slanted arm

●Table mounting column

●Choose any six safety clutch tapping adapters

●Eletric – Controlled Device

Optional Device

●90° and Various degree tapping device

●TM 800030 Automatic tap lubricator system

●TM 800032 Cast iron work cart