- Drilling and Tool Grinding Machine

- Foam Gasket Forming Machines

- Vacuum cleaners

- Vertical lathes

- Carbide Application Equipment

- Workshop Machinery

- Tapping Machine

- Hydraulic Ironworker

- CNC Drilling and Milling machine

- Drilling and Milling machine

- Bench Drilling Machine

- Pillar type drilling machine

- CNC Lathes

- Sheet Metal Angle Notching Machine

- CNC Precision 4-high Roller Leveling Machine

- Fastener Insertion Machine

- Hydraulic Punching Machine

- Special Offer

- Radial Drilling Machines

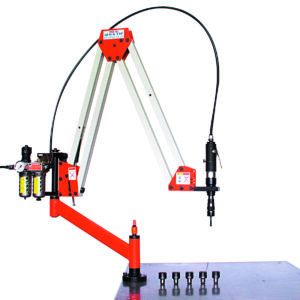

Type HMT-22,32,42,50 – Hydraulic Tapping Machine

Hydraulic Tapping Machines Type HMT-22, 32, 42, 50 offer exceptional efficiency and control for demanding thread tapping applications in industrial settings. These robust machines use a hydraulic system to provide unmatched power and precision, making them ideal for high-volume production lines and workshops. Key features include:

– Powerful Hydraulic Operation: The efficient hydraulic system ensures smooth and consistent tapping, handling a wide range of materials with ease.

– Extended Working Range: With a reach of up to 1900mm, these tapping machines offer excellent flexibility for various tapping needs.

– Versatile Tapping Capacity: Accommodates taps from M3 to M50 (metric thread sizes), covering a broad range of project requirements.

– Movable Arm Design: The movable arm improves control and maneuverability when tapping in tight or hard-to-reach spaces.

– User-Friendly Controls: An intuitive control panel simplifies operation, reducing setup time and boosting workflow efficiency.

– Safety Features: Overload protection and an emergency stop function ensure operator safety during use.

– Integrated Work Cart: The included work cart with a T-slotted platform provides a stable workspace for material handling and workpiece positioning.

– Standard Accessories: Includes a hydraulic tapping spindle, stretch arm, slanted arm, table mounting column, and safety clutch tapping adapters (specific number may vary).

Benefits of the HMT-22, 32, 42, 50:

– Enhanced Productivity: The hydraulic operation and wide working range reduce tapping cycle times, improving production efficiency.

– Effortless Power for Tough Materials: The hydraulic system ensures consistent torque, making it ideal for tapping tough materials like thick metals and high-strength alloys.

– Precise Thread Creation: The machine’s control and rigidity help produce clean, consistent threads, minimizing rework and enhancing product quality.

– Operator Comfort: The movable arm design and easy-to-use controls reduce operator fatigue during extended use.

– Wide Applications: These tapping machines are suitable for automotive, aerospace, metalworking, and other industries requiring high-performance tapping solutions.

The HMT-22, 32, 42, 50 Hydraulic Tapping Machines are ideal for:

– High-volume production lines that demand top performance and efficiency.

– Workshops needing a robust and reliable tapping solution for tough materials.

– Industries that prioritize consistent, high-quality thread creation.

Product ID: HMT-22, 32, 42, 50

These machines primarily rely on hydraulic operation. The work cart features a T-slot platform, and the working range extends up to 1900mm with a tapping capacity from M3 to M50. The movable arm design ensures easy operation, and the included work cart provides stability. Depending on the work conditions, additional accessories can be purchased to enhance functionality. For businesses seeking reliable **tapping machines in UAE**, the HMT series offers an efficient and versatile solution for demanding applications.

Product Character

| Model | HMT-22 | HMT-32 | HMT-42 | HMT-50 |

| For Tap | M3 ~ M22 | M4 ~ M32 | M4 ~ M42 | M8 ~ M50 |

| Speed (rpm)(rpm) | 0 – 400 | 0 – 500 / 0 – 105 | 0 – 400 / 0 – 75 | 0 – 360 / 0 – 60 |

| Work Range | HMT-22,32,42 : Rmax 1900mm Rmin 200 mm / HMT-50 : Rmax 1600mm Rmin 200 mm | |||

| Voltage | 220/380V, 50/60 Hz, 3-PHASE | |||

| Electric Motor (kg) | 3HP | 3HP | 3HP | 5HP |

| Hydraulic Pressure (kg) | 100 kg/cm2 | 100 kg/cm2 | 100 kg/cm2 | 140 kg/cm2 |

| N.W/G.W (kg) (kg) | 400 / 500 | 400 / 500 | 400 / 500 | 400 / 500 |

Standard Accessories

●Hydraulic tapping spindle

●Stretch arm

●Slanted arm

●Table mounting column

●Choose any six safety clutch tapping adapters

●Work Cart

●Eletric Motor, Hydraulic Pump, Hydraulic Box

●Eletric – Controlled Device

Optional Device

●TM 800030 Automatic tap lubricator system

●TM 800035 90° and Various degree tapping device

●TM 800036 Depth Controllrt