Safety Protocols for Tapping Machines: Preventing Thread Stripping and Hand Injuries

Tapping machines are an essential part of every workshop and manufacturing site, allowing operators to create accurate internal threads in metals, plastics, and other materials. Industries such as automotive, electronics, and aircraft manufacturing utilize tapping machines extensively. Tapping machines are fantastic tools, but they also come with safety liabilities. Stripped threads, damaged workpieces, and hand injuries can all occur if operators do not operate tapping machines safely.

Understanding potential hazards when using tapping machines and taking precautions to minimize risks is imperative to ensure workshop safety. Shopping with a reputable supplier can also greatly reduce the risk of safety incidents by supplying reliable and safe equipment with guidance on safe operation.

Understanding the Risks

Are you using a tapping machine? Two clear hazards should be noted:

1. Thread Stripping – Either from excessive torque, misalignment, not using sufficient lubrication,/or the wrong tap size. Thread stripping will result in slower production, damaged parts, and an increased cost.

2. Hand Injuries – When the operator’s hands are too close to moving parts, they can be injured by cuts, nipped or crushed fingers, among various lacerations. Hand injuries are particularly hazardous when an operator is using a hand-operated or semi-automatic machine.

Identifying these risks lays the foundation for creating a safer workplace.

Choosing the right tapping machine:

Tapping machines are very different with regard to one compared to another. Equipping workers with the right tools helps prevent accidents. Below you will discover points to contemplate before making your purchase:

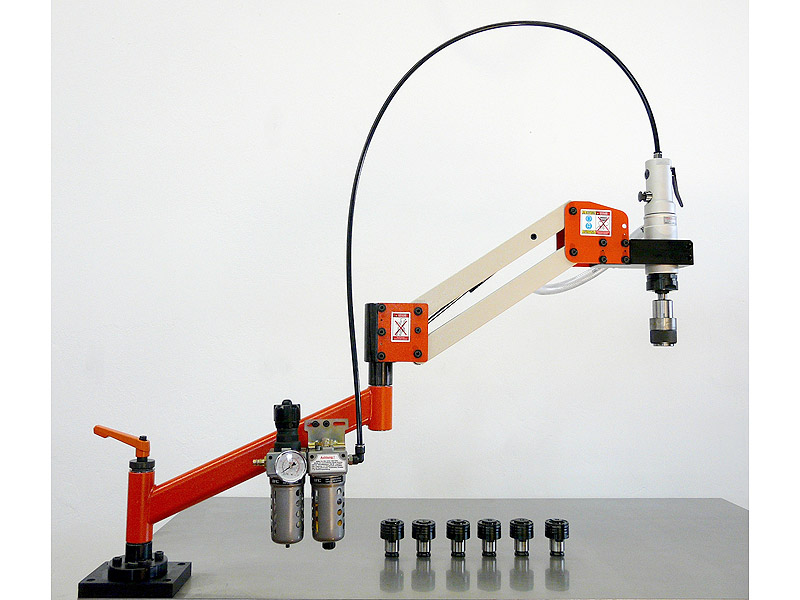

– Types of Machine: Fully automatic machines eliminate the need to hold the workpiece firmly in place, thus eliminating unnecessary hand contact and risk of injury. Pneumatic or hydraulic machines will have the added benefit of recursively providing better torque control and torque consistency.

– Capacity & Precision: Check that the machine will be able to handle the thickness of your material and the sizes of threads required. A machine, either way too large or too small, may result in threads stripping.

– Safety Features: Identify if the machine has emergency shut-down buttons, torque limiters, protective guards around moving components, and sensors to detect unacceptable angular misalignment or excessive resistance to rotation.

Selecting the appropriate machine allows you to improve safety, increase productivity, and minimize material wastage.

Proper Setup and Maintenance

Even the safest machine can be hazardous if not properly set up. Follow these steps:

Secure the Workpiece: Clamp workpieces firmly to prevent slipping and misaligned threads.

Lubrication: Use the correct cutting fluid to reduce friction and heat, preventing thread stripping and extending tap life.

Correct Tap Selection: Choose the right tap size and type for your material and thread pitch. The wrong tap can ruin a workpiece quickly.

Regular Maintenance: Inspect machines for worn parts, loose components, or damaged guards. Proper maintenance prevents accidents from equipment failure.

Safe Operating Procedures

Safe Procedures: Protecting the operator and material

Follow these safe procedure practices to protect yourself and the work you will do:

1. Keep Hands Away: Always keep hands away from moving tap cones, etc. and use push sticks or clamps whenever possible.

2. Start Slow: Always start threading using low speed to allow the tap to be properly positioned before increasing speed.

3. Watch for Torque: Do not force the tap into the work material. If it is too hard to keep turning the tap, stop and find out what is wrong.

4. Use Guards and Shields: Never remove any guards! Guards keep you safe, and shields keep the debris contained.

5. Training: A well-trained operator will tend to make fewer mistakes and will be safer.

Personal Protective Equipment (PPE)

PPE will provide a layer of extra protection, including:

- cut-resistant gloves for the hands

- safety glasses or face shields for the eyes

- protective aprons to prevent clothing from catching

Emergency Preparedness

Even if we take precautions, incidents can happen. Be prepared to limit any damage you could incur:

- Make sure your emergency stop buttons are easily accessible and work

- Maintain a stocked first aid kit with an appointed person who has basic first aid training.

- Always post safety instructions in prominent places near your tapping machines.

Working with a reputable workshop machine dealer:

A true equipment dealer is more than a store, they should also provide you with:

- Advice on choosing the right machine

- Service to install, maintain, or repair your machine

- Safety and other training

Having a reputable machine supplier also means you will have a safe, reliable machine and someone to refer to when you need support.

Conclusion

Tapping machines are powerful machines that deserve to be used properly and respected. By following safety protocols – selecting the proper machine, securing the workpiece, lubricating properly, wearing PPE, and training operators – you can avoid thread stripping and hand injuries. Choose a reputable workshop equipment supplier such as Rockwood Workshop Machines, and you will be assured of a quality machine with excellent support. Safety should always be the first priority as it not only protects your team but also increases productivity and saves time and resources lost by damaged parts.