Hydraulic Ironworker Machines: Simple Safety Tips Every Operator Should Know

Hydraulic Ironworker machines are fantastic pieces of equipment for any metalworking shop. They can punch, shear, bend, and notch metal quickly and accurately. They’re incredibly powerful, but using them the wrong way can lead to trouble. That’s why it’s essential to follow some basic safety rules whenever you operate a hydraulic ironworker.

Whether you are new to the workshop or have a lifetime of experience, safety must remain your priority. In this blog, we’ll provide simple safety tips as well as our thoughts on how choosing the right workshop equipment suppliers can improve your business.

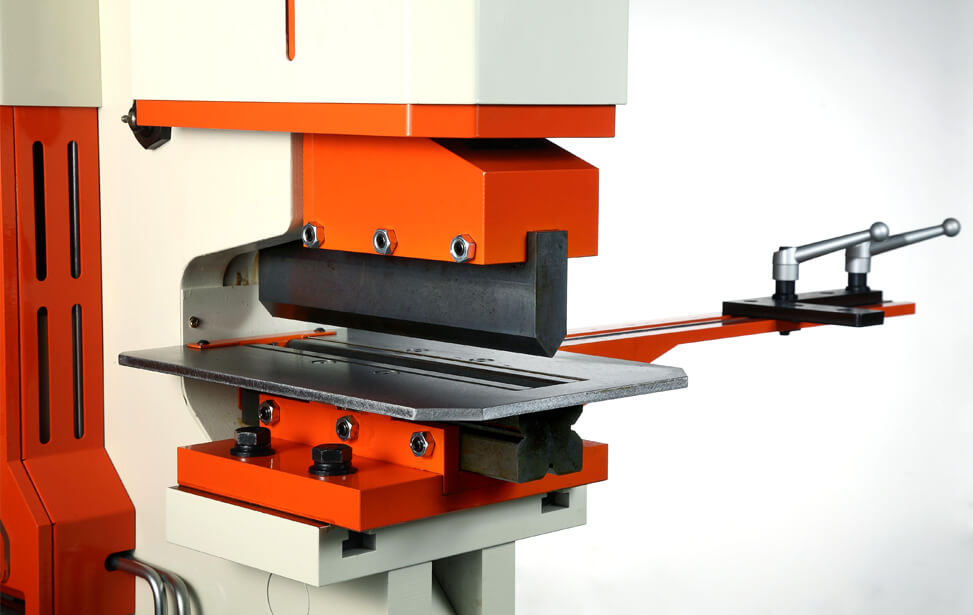

What is a Hydraulic Ironworker?

A hydraulic ironworker is a machine that uses hydraulic pressures to cut, punch, and form metal. If you have different work stations, you can get a lot done using only one machine. Hydraulic ironworkers are powerful, and designed to travel with speed, which is perfect for a busy shop.

Due to the various force levels involved, accidents and damage can occur if hydraulic ironworkers are not used properly with respect. Safety is paramount.

Easy Safety Tips for Using a Hydraulic Ironworker

1. Get Proper Training

Before touching a hydraulic ironworker, make sure you get trained on how to use it. You need to know how the machine works, what the controls do, and what to do if something goes wrong. Many trusted workshop equipment providers offer training when you buy machines from them, so don’t skip it!

2. Check the Machine Before You Start

Always take a few minutes to inspect the machine before using it. Look for:

- Leaks or low hydraulic fluid

- Loose bolts or parts

- Cracks in hoses or fittings

- Damaged safety guards

- Problems with pedals or buttons

If you see anything wrong, fix it first. Never try to “just work through it” — it’s not worth the risk.

3. Wear the Right Safety Gear

Protect yourself! When using a hydraulic ironworker, always wear:

- Safety glasses or a face shield

- Heavy gloves

- Steel-toed boots

- Hearing protection

- Close-fitting clothes (no loose sleeves or jewelry)

This basic gear can save you from serious injuries.

4. Clamp Your Workpiece Properly

Make sure the piece of metal you’re working on is secure before you start. If it’s loose, it can fly out at high speed when the machine moves — and that can be very dangerous.

Good machines from top workshop equipment providers often come with better clamps and supports to help keep your work safe and steady.

5. Keep Hands Away from Moving Parts

Never put your hands near the blades, punches, or moving parts — even if the machine is off. Some hydraulic parts can still move unexpectedly. Always use tools to move metal pieces if you need to adjust them.

6. Know Your Machine’s Limits

Every hydraulic ironworker has a limit. Don’t try to punch or cut metal that’s too thick or hard for the machine. Overloading it can cause the machine to break, or worse, cause a serious accident. Always follow the manufacturer’s guidelines.

When you buy from a trusted workshop equipment provider, they’ll give you all the manuals and charts you need to know your machine’s safe limits.

7. Keep the Machine and Tools in Good Shape

Sharp blades and clean, well-oiled machines work better and are safer. Regularly check and maintain:

- Blades (sharpen or replace when needed)

- Punches and dies (swap out when worn)

- Hydraulic oil (keep it clean and topped up)

A little time spent on maintenance can prevent a lot of trouble later.

8. Know How to Stop the Machine Fast

Know exactly where to find the emergency stop button and how to use it. It should always be easy to reach. Learn how to respond before problems happen, so you don’t panic when something goes wrong.

Why Choosing the Right Workshop Equipment Provider Matters

Choosing the right machine matters just as much as using it safely. A good workshop equipment provider like Rockwood Workshop Machines will:

- Sell you machines that meet safety standards

- Help you with installation and training

- Offer quick service and support

- Provide spare parts and maintenance help

Buying from a trusted supplier gives you peace of mind that you’re getting a safe, reliable machine and support if you ever need it.

Hydraulic ironworkers are powerful machines that can make your work faster and easier — but only if you use them safely. With the right training, daily checks, proper safety gear, and good equipment, you can keep your workshop safe and productive.

And remember, whenever you need new machines or advice, always reach out to a reliable workshop equipment provider in the UAE. They can guide you in selecting the right tools for the job and keep your team working safely.

To read more blogs, click here: The Productivity Benefits of Fastener Insertion Machines