Menu

Categories

- Drilling and Tool Grinding Machine

- Foam Gasket Forming Machines

- Vacuum cleaners

- Vertical lathes

- Carbide Application Equipment

- Workshop Machinery

- Tapping Machine

- Hydraulic Ironworker

- CNC Drilling and Milling machine

- Drilling and Milling machine

- Bench Drilling Machine

- Pillar type drilling machine

- CNC Lathes

- Sheet Metal Angle Notching Machine

- CNC Precision 4-high Roller Leveling Machine

- Fastener Insertion Machine

- Hydraulic Punching Machine

- Special Offer

- Radial Drilling Machines

Type AT-08,12/II Pneumatic Tapping Ma...

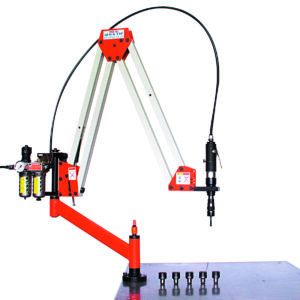

The Type AT-08,12/II Pneumatic Tapping Machine is a powerful tool designed to handle tough internal thread tapping tasks in workshops and industrial settings. Powered by air, it offers a wide working range and excellent tapping capacity, making it perfect for projects that require both precision and deep access.

Key Features of the AT-08,12/II:

- Efficient Pneumatic Operation: The air-powered motor ensures smooth and easy tapping, even with tough materials.

- Wide Working Range: With a reach of up to 1900mm, the AT-08,12/II reduces the need to reposition the machine, saving time.

- Versatile Tapping Capacity: It can handle a range of tap sizes, from M2 to M12, making it suitable for various projects.

- Easy Control and Maneuvering: The movable arm design gives operators full control, especially when working in tight spaces or with deep workpieces.

- User-Friendly: The simple control panel makes operation easy, even for users with less experience.

- Safety Features: Includes overload protection and an emergency stop function for added safety.

- Optional Accessories: Enhance its capabilities with additional tapping attachments and safety clutches (availability may vary).

Benefits of the AT-08,12/II:

- Efficient for Deep Workpieces: The long working range allows you to tap deep workpieces or those with limited access, offering more flexibility.

- Boosts Productivity: The powerful operation and long reach reduce setup time, making the tapping process faster and more efficient.

- High Accuracy: The movable arm design ensures precise control, resulting in clean, consistent threads.

- Less Operator Fatigue: The ergonomic design helps reduce strain, allowing for more comfortable use during extended periods.

- Wide Application: Perfect for industries such as automotive, metal fabrication, furniture manufacturing, and electrical assembly lines.

The Type AT-08,12/II Pneumatic Tapping Machine is perfect for:

- Workshops and production facilities that need a powerful tapping solution with long reach.

- Projects that require precise threads in deep or hard-to-reach areas.

- Industries looking to improve tapping efficiency and productivity, especially in high-volume operations.

Product ID: AT-08,12/II

This air-powered machine has a working range of up to 1900mm and can tap sizes from M2 to M12. It's easy to assemble, and the movable arm design ensures simple and convenient operation. Additional accessories can be purchased for multi-functional tapping based on your needs.

Enquiry

Type HM-22,32,42,50 – Hydraulic...

The Type HM-22,32,42,50 Hydraulic Tapping Machine offers unparalleled power and precision for demanding thread tapping applications in industrial environments. This heavy-duty machine utilizes hydraulic operation to deliver exceptional performance and efficiency, making it ideal for high-volume production lines and workshops.

Key Features of the HM-22,32,42,50:

Robust Hydraulic Operation: The hydraulic system guarantees consistent and powerful tapping, tackling even the toughest materials with ease.

Extensive Working Range: With a working range of up to 1600mm (maximum reach), the HM-22,32,42,50 offers exceptional flexibility for diverse tapping needs.

Unmatched Tapping Capacity: This machine boasts a wide tapping capacity range, handling taps from M3 to M50 (metric thread sizes), making it suitable for a broad spectrum of projects.

Movable Arm Design: The included movable arm provides operators with optimal control and maneuverability for precise tapping, even in tight spaces.

User-Friendly Controls: The intuitive control panel simplifies operation and minimizes setup time, allowing for efficient workflow integration.

Safety Focus: Operator safety is prioritized with overload protection and an emergency stop function.

Standard Accessories: The HM-22,32,42,50 comes equipped with a hydraulic tapping spindle, stretch arm, slanted arm, table mounting column, and a selection of safety clutch tapping adapters (specific number may vary).

Benefits of the HM-22,32,42,50:

Enhanced Production Efficiency: The powerful hydraulic operation and extensive working range ensure faster tapping cycles, leading to significant productivity improvements.

Effortless Power for Demanding Applications: The hydraulic system delivers consistent torque, making it ideal for tapping challenging materials such as thick metals and high-strength alloys.

Exceptional Thread Quality: The precise control and rigidity of the machine contribute to creating clean and consistent threads, minimizing rework and optimizing product quality.

Reduced Operator Fatigue: The ergonomic design and easy operation minimize operator strain during extended use.

Versatility for Diverse Industries: The HM-22,32,42,50 caters to a wide range of applications in automotive, aerospace, general metalworking, and other demanding industries.

The Type HM-22,32,42,50 Hydraulic Tapping Machine is ideal for:

High-volume production lines seeking maximum efficiency and performance.

Workshops requiring a robust and reliable tapping solution for challenging materials.

Industries prioritizing consistent high-quality thread creation.

Enquiry

- Product ID: HM-22,32,42,50Mainly relies on hydraulic to operate, working range is up to 1600mm, tapping capacity is M3~M50. Can be used for the production of inner hole threads of different sizes. The stand is designed as a movable arm, providing the user with an easy and convenient way to operate. Include work cart. According to the working conditions, accessories can also be purchased to achieve multi-functional tapping.

Type HMT-22,32,42,50 – Hydrauli...

Hydraulic Tapping Machines Type HMT-22, 32, 42, 50 offer exceptional efficiency and control for demanding thread tapping applications in industrial settings. These robust machines use a hydraulic system to provide unmatched power and precision, making them ideal for high-volume production lines and workshops. Key features include:

- Powerful Hydraulic Operation: The efficient hydraulic system ensures smooth and consistent tapping, handling a wide range of materials with ease.

- Extended Working Range: With a reach of up to 1900mm, these tapping machines offer excellent flexibility for various tapping needs.

- Versatile Tapping Capacity: Accommodates taps from M3 to M50 (metric thread sizes), covering a broad range of project requirements.

- Movable Arm Design: The movable arm improves control and maneuverability when tapping in tight or hard-to-reach spaces.

- User-Friendly Controls: An intuitive control panel simplifies operation, reducing setup time and boosting workflow efficiency.

- Safety Features: Overload protection and an emergency stop function ensure operator safety during use.

- Integrated Work Cart: The included work cart with a T-slotted platform provides a stable workspace for material handling and workpiece positioning.

- Standard Accessories: Includes a hydraulic tapping spindle, stretch arm, slanted arm, table mounting column, and safety clutch tapping adapters (specific number may vary).

Benefits of the HMT-22, 32, 42, 50:

- Enhanced Productivity: The hydraulic operation and wide working range reduce tapping cycle times, improving production efficiency.

- Effortless Power for Tough Materials: The hydraulic system ensures consistent torque, making it ideal for tapping tough materials like thick metals and high-strength alloys.

- Precise Thread Creation: The machine’s control and rigidity help produce clean, consistent threads, minimizing rework and enhancing product quality.

- Operator Comfort: The movable arm design and easy-to-use controls reduce operator fatigue during extended use.

- Wide Applications: These tapping machines are suitable for automotive, aerospace, metalworking, and other industries requiring high-performance tapping solutions.

The HMT-22, 32, 42, 50 Hydraulic Tapping Machines are ideal for:

- High-volume production lines that demand top performance and efficiency.

- Workshops needing a robust and reliable tapping solution for tough materials.

- Industries that prioritize consistent, high-quality thread creation.

Product ID: HMT-22, 32, 42, 50

These machines primarily rely on hydraulic operation. The work cart features a T-slot platform, and the working range extends up to 1900mm with a tapping capacity from M3 to M50. The movable arm design ensures easy operation, and the included work cart provides stability. Depending on the work conditions, additional accessories can be purchased to enhance functionality. For businesses seeking reliable **tapping machines in UAE**, the HMT series offers an efficient and versatile solution for demanding applications.

Enquiry

Vertical Lathes BVL 1250 H

Vertical lathe machines, especially the VTL H series, are built to meet the tough demands of industries like Oil & Gas, Earth Moving, and Automotive manufacturing. These machines feature a durable cast iron bed and column, providing excellent thermal stability for long-lasting accuracy and performance. With a strong box-type construction, heavy-duty spindle, and high-speed, bi-directional servo turret, they offer outstanding rigidity and stability. The wide box guideways help ensure smooth, vibration-free cutting, even with large and heavy parts. The VTL series is perfect for machining large components like valve bodies, motor bodies, brake drums, and disc brakes. If you're in the UAE and need reliable lathe machines, Rockwood Workshop Machines can provide solutions tailored to your needs.

Enquiry

Vertical Lathes BVL 800ML

Vertical lathes, specifically the BVL 800ML, are designed as a "Done-in-One" solution, aiming to reduce production time and ensure precise component accuracy. This advanced machine seamlessly integrates various machining processes, enhancing efficiency and precision, making it an ideal choice for modern manufacturing requirements.

Boost your machining capabilities by purchasing your lathe machines from Rockwood Workshop Machines in the UAE today!

Enquiry

Vertical Lathes BVL 900H

Vertical lathe machines, specifically the VTL H series, are designed for demanding industries like Oil & Gas, Construction, and Automotive. Made with strong cast iron, they maintain stability and accuracy. These machines are exceptionally rigid and perform well. With a robust design, powerful spindle, and smooth movement, they ensure vibration-free cutting. The VTL series excels in machining large components like valve bodies and brake drums.

For more information on the VTL H series, visit Rockwood Workshop Machines for the best vertical lathe machines in the UAE.

Enquiry

Vertical Lathes BVL R L

Vertical lathe machines from the BVL Ram type series are built to handle large, heavy workpieces, giving manufacturers a reliable and powerful tool for demanding jobs. These machines can perform basic tasks like turning, boring, and deep boring, as well as more complex operations like drilling, tapping, milling, and even intricate shaping.

Made from a single solid piece, these Ram-type vertical lathes are very stable and strong, ensuring high-quality results. They can easily turn motor bodies, wheels, drums, and various parts needed for industries like railways, shipping, construction, and power generation. These robust machines also make it easy to load and secure heavy, large components.

Unlock your machining potential with Rockwood Workshop Machines! Our vertical lathe machines are available across the UAE and GCC.

Enquiry

Vertical Lathes BVL R L CF

Vertical lathes machine from the BVL RLCF series are engineered to accommodate large, heavy workpieces, offering manufacturers a dependable, high-performance solution for heavy-duty applications. These machines support fundamental turning, boring, and deep boring operations, as well as turn-mill applications such as drilling, tapping, milling, helical interpolation, thread milling, and profile machining.

Experience the power of BVL RLCF series lathe machines in UAE.

Enquiry

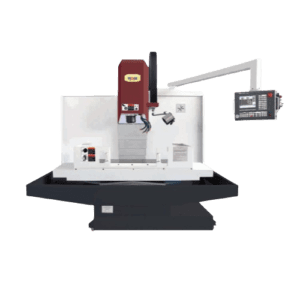

XK series- CNC Drilling and Milling M...

The XK713/XK714 CNC drilling and milling machine is a versatile and precise industrial tool designed for efficient machining. With advanced CNC technology, it provides high-speed drilling and milling capabilities with great accuracy, making it ideal for various manufacturing and engineering applications. This machine has a strong and stable structure, along with a rigid spindle design, which reduces vibration and ensures smoother operations, improving the quality of the finished products. Its multi-axis control system allows for complex machining tasks, making it easy to create intricate designs and precise shapes. Featuring a user-friendly interface and intuitive controls, operators can easily set up and monitor machining processes, boosting productivity and reducing downtime. Whether you're working on prototypes, small batches, or large-scale production, the XK713/XK714 CNC drilling and milling machine offers reliable performance and consistent results. It's a valuable tool for industries that rely on drilling and milling machines in the UAE.

Enquiry

Z Series – Radial drilling mach...

Z3050X12/1

The radial drilling machine Z3050X12/1 is built for strength and precision, offering a drilling capacity of up to 50mm in steel. Designed for demanding industrial applications, it features a hydraulic clamping system for secure workholding, a range of spindle speeds for versatility, and a powerful motor capable of handling heavy-duty tasks. This radial drilling machine is an ideal choice for industries in the UAE that rely on high-performance drilling and milling machines for their operations.

Z3040X13/1

The radial drilling machine Z3040X13/1 combines flexibility and efficiency, with a 40mm drilling capacity in steel. It features a swiveling radial arm for easy access to workpieces from different angles, an automatic feed system for continuous operation, and variable speed control to handle various materials and tasks. This radial drilling machine is perfect for workshops in the UAE that need versatile and efficient drilling and milling machines for their operations.

Z3032X10/1

The radial drilling machine Z3032X10/1 is compact yet powerful, designed for precision drilling in smaller workshops. With a drilling capacity of 32mm in steel, it offers hydraulic pre-selection for speed and feed adjustments, a high-rigidity design that reduces vibrations, and an extendable arm for enhanced reach and flexibility. This radial drilling machine is an excellent choice for workshops in the UAE that require reliable and precise drilling and milling machines in limited spaces.

Z3040X10/1

The radial drilling machine Z3040X10/1 is built for efficiency and ease of use. With a 40mm drilling capacity in steel, it features a hydraulic clamping system for stability, a 360-degree rotating arm for flexibility, and variable speed control to handle a range of materials and tasks. This radial drilling machine is designed for both light and heavy-duty work, making it an essential tool for industries in the UAE that depend on reliable drilling and milling machines.

Standard Accessories

Enquiry

- Box-shaped worktable

- Taper sleeve

- Tool releasing wrench

- Drift

- Eyelet bolts

Z3050x16/1 – Radial Drilling Ma...

Radial drill machine Z3050x16/1, available from Rockwood Workshop Machines as part of the range of drilling and milling machines in UAE, is a versatile and durable tool designed for high precision and efficiency in industrial environments. Some of its key features include:

Enquiry

- Heavy-duty Construction: Made with a strong cast iron frame, it offers stability and reduces vibrations, ensuring accurate drilling.

- Wide Drilling Capacity: With its long arm reach and high drilling capacity, it can handle large and complex workpieces with ease.

- 360-Degree Arm Rotation: The arm can rotate fully, providing flexibility for various drilling angles and positions.

- Variable Speed Control: Adjustable speed settings ensure optimal performance for different materials and tasks.

- Hydraulic Clamping System: Keeps the arm and head securely in place, improving precision during operation.

- Advanced Feed Mechanism: The sophisticated feed system ensures smooth and accurate drilling movements.

- User-friendly Design: With easy-to-use controls and clear displays, it reduces operator fatigue and simplifies operation.

- Safety Features: The machine is equipped with overload protection, emergency stop buttons, and protective guards to ensure a safe working environment.

ZK-12Y – CNC Drilling and Tappi...

CNC drilling and tapping machines, such as the ZK-12Y, are designed for precise and efficient drilling and tapping tasks. With advanced CNC technology, it provides fast performance and precise control, making it perfect for various industries. It can handle drilling and tapping on different materials, including metals and plastics, with great accuracy and speed. The machine is easy to use, with simple controls and a clear interface, allowing for quick setup and smooth integration into production lines. Whether for small or large production runs, the ZK-12Y consistently delivers reliable results, boosting productivity and reducing manufacturing costs.

Key features:

- High precision

- High efficiency

- Attractive design

- Multi-functional

- Flexible configurations

Enquiry

ZK7045 B/B1 – Drilling and Mill...

Drilling Machines, like the ZK7045 B/B1, are designed for precise drilling and milling tasks on various materials. With its strong build and efficient design, this machine is perfect for both small workshops and larger industrial settings. It comes with a powerful motor and adjustable speed settings, allowing for precise control over drilling and milling, ensuring accurate results every time. The ZK7045 B/B1 is easy to use, featuring a user-friendly interface and ergonomic design that improves comfort and efficiency during long work sessions. Reliable, versatile, and precise, this machine is an essential tool for both professionals and hobbyists, making it easy to handle a wide range of drilling and milling tasks.

Standard Accessories:

Enquiry

- 16mm Drill Chuck

- 80mm Cutter

- Taper Sleeve

- Arbor

- Drift

- Wrench

- Drawbar

ZQ3040x10/1 – Radial Drilling M...

Radial drilling equipment, such as the ZQ3040x10/1 Radial Drilling Machine, is a versatile and robust tool designed for precision drilling across various materials. This machine features a swiveling and adjustable radial arm, offering flexible and efficient operations, particularly for large and heavy workpieces. With a maximum drilling capacity of 40mm in steel, it delivers exceptional performance suited for industrial applications.

Key features of the ZQ3040x10/1 include:

Hydraulic Clamping System: Provides secure and stable positioning of the arm, column, and workpiece, ensuring accurate drilling operations.

Variable Speed Control: Offers a wide range of spindle speeds, allowing for optimal performance tailored to different materials and drill sizes.

Automatic Feed Mechanism: Increases productivity by enabling continuous and uniform drilling without the need for manual intervention.

360-Degree Arm Rotation: Facilitates easy access to the workpiece from multiple angles, enhancing operational flexibility.

Heavy-Duty Construction: Built with high-quality materials to withstand rigorous use, ensuring long-lasting durability and reliability.

Ideal for both small workshops and large manufacturing plants, the ZQ3040x10/1 Radial Drilling Machine combines efficiency, precision, and ease of use to meet a variety of drilling needs. For high-performance drilling and milling machines in the UAE, Rockwood Workshop Machines provides trusted solutions that cater to diverse industrial requirements.

Enquiry

ZQ3050x20/1 – Radial Drilling M...

Radial drilling machine ZQ3050x20/1, offered by Rockwood Workshop Machines, is a versatile and reliable tool for precise drilling operations. With an adjustable radial arm, it provides flexibility for drilling on various materials and workpieces. Ideal for both drilling and milling tasks, this machine is perfect for industries such as metalworking and manufacturing. As part of the range of drilling and milling machines in UAE, the ZQ3050x20/1 ensures high accuracy and efficiency, making it a dependable choice for a wide range of applications.

Enquiry

ZSK-12Y – CNC Drilling and Tapp...

CNC drilling and tapping machines, like the ZSK-12Y, are advanced automated systems designed for precise and efficient drilling and tapping operations. Featuring cutting-edge CNC technology, the ZSK-12Y ensures high accuracy and productivity in tasks such as hole drilling and thread tapping. Ideal for use in manufacturing, automotive, and industrial applications, it streamlines complex processes, reduces manual effort, and delivers consistent, high-quality results.

Enquiry

- High precision

- High efficiency

- High facevalue

- Multi function

- Flexible configurations

Product Categories

- Bench Drilling Machine

- Carbide Application Equipment

- CNC Drilling and Milling machine

- CNC Lathes

- CNC Precision 4-high Roller Leveling Machine

- Drilling and Milling machine

- Drilling and Tool Grinding Machine

- Fastener Insertion Machine

- Foam Gasket Forming Machines

- Hydraulic Ironworker

- Hydraulic press

- Hydraulic Punching Machine

- Pillar type drilling machine

- Radial Drilling Machines

- Sheet Metal Angle Notching Machine

- Tapping Machine

- Vacuum cleaners

- Vertical lathes