The Productivity Benefits of Fastener Insertion Machines

Today’s manufacturing environment is highly competitive, and companies are constantly seeking to become more efficient at lower costs and increase production. Fastener insertion machines have been one of the biggest innovations that have disrupted many industries and are now widely utilized across numerous industrial sectors operated by assembly lines in auto manufacturing, electronics, aerospace, and many more. They automate the process of inserting fasteners like screws, bolts, and nuts, bringing numerous benefits that help manufacturers stay ahead of the curve.

What Are Fastener Insertion Machines?

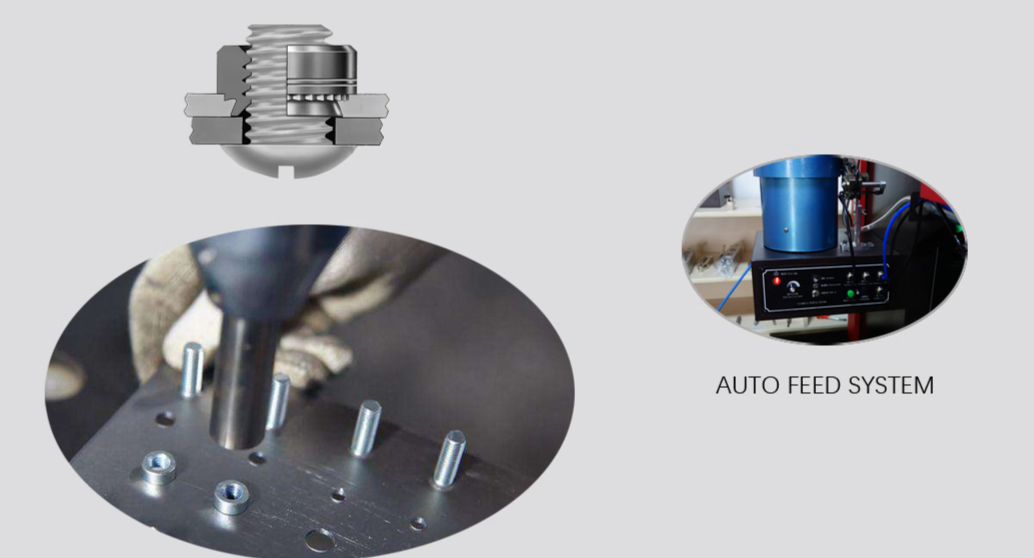

Fastener insertion machines are designed to automate the fastening process for fasteners in parts or components during assembly. These machines can easily feed, align, and insert fasteners into components quickly and accurately. And these machines are built to be used in the assembly application for high-speed assembly lines or within an industry that requires recurring and critical fastener insertions.

Fastener insertion machines help to improve the fastening process by increasing production rates, as there is consistent quality and limited human intervention, and fewer inconsistencies, which leads to better flow throughout the entire manufacturing process.

Boosting Speed and Efficiency

One of the most significant advantages of fastener insertion machines is the speed they bring to the manufacturing process. Manual insertion of fasteners often takes up valuable time, particularly when handling high volumes of components. Automated fastener insertion machines can handle these tasks much faster, often inserting hundreds or thousands of fasteners per hour, depending on the machine’s specifications.

The overall advantage in speed enables manufacturers to produce faster, thus meeting higher production rates and increased operational efficiency. In situations when time is of the essence, i.e., automotive or consumer electronics, increasing speeds while producing accuracy without loss of quality, can be a valuable competitive advantage.

Precision and Consistency

Another added value of fastener insertion machines is the fact that they can provide excellent accuracy and consistency. The operator could accidentally misplace a fastener, apply too much or too little pressure, and misalign the fastener, and so on, resulting in defects. Manual fastener installation is prone to mistakes caused by human error. Fastener insertion machines, on the other hand, can install fasteners with remarkable accuracy every time, making sure each fastener is installed to the right depth at the correct angle. The consistency that fastener machines provide is important for maintaining quality, particularly in industries where a small mistake can cost money and adversely affect product performance.

By automating the insertion process, manufacturers can ensure that standards do not begin to slip as they ramp up production, also reducing the likelihood of operators making mistakes, resulting in improved product quality and enhanced customer satisfaction.

Reducing Labor Costs

Fastener insertion machines also reduce the need for manual labor, helping cut down overall staffing expenses. Manual fastening depends on skilled laborers to carry out the repetitive job and can be expensive, especially in today’s labor market. However, fastener insertion machines are able to help manufacturers minimize the reliance on manual labor by allowing them to redeploy employees to other, more complex or added-value tasks.

The use of automation also has the added benefit of reducing the impacts of human fatigue or injury because the workers are not subjected to prolonged hours of doing work that is either physically demanding or repetitive. That translates into better productivity and more manageable operating expenses.

Enhanced Workplace Safety

The area of workplace health and safety is another area in which fastener insertion machines shine. Research has shown that manual fastening processes can be physically strenuous, lead to repetitive stress injuries, and cause accidents in the workplace due to the repetitive nature of the task. Utilizing fastener insertion machines automates fastening processes, thus reducing the likelihood of these types of injuries and allowing for a better work environment for employees.

Additionally, automation considerably reduces errors caused or exacerbated by human fatigue; longer fatigue lengthens assembly lead time and creates predictability in fastening that is safer.

Improved Product Quality

Fastener insertion machines are a valuable part of the overall quality of the final product. In industries such as aerospace, automotive, and electronics, where precision is critical, it’s essential that fasteners are consistently and accurately placed. These machines deliver fasteners in the same way, each time, therefore, they are ensuring the highest quality is being delivered.

The consistent insertion of fasteners plays an important role in maintaining the structure of the product with no risk of it malfunctioning. This enables the manufacturer to deliver a product that meets or exceeds customer expectations while simultaneously improving brand reputation and customer loyalty.

Flexibility for Various Applications

Fastener insertion machines is most impressive for their flexibility. They are made for inserting a variety of different materials and fasteners for many different applications. It does not matter if you need to insert small electronic screws, or large bolts for industrial applications, the machine can be configured to suit your particular requirements.

This flexibility makes them perfect for any company that manufactures different products or changes production lines often.

Reducing Waste and Improving Sustainability

In addition to minimizing the likelihood of waste, fastener insertion machines provide exact control of the fastening process. Human operators can misapply fasteners in several ways, including over-tightening, under-tightening, or missing the part entirely. Each of these mistakes results in wasted materials, time, or part breakage. Automated machines completely remove this process variability and virtually ensure fasteners are inserted correctly.

Many fastener insertion machines are designed with energy efficiency features, too, which can help reduce manufacturing energy costs. This can be beneficial in terms of sustainability as well as reducing the business’s broader environmental impact.

The productivity benefits of fastener insertion machines are clear. By automating the fastening process, businesses can work more efficiently; achieve greater precision, lower operational expenses, and boost the overall quality of their products. These machines also contribute to a safer work environment and help companies become more adaptable and sustainable in the long run.

As a leading industrial equipment supplier in UAE, Rockwood Workshop Machines offers state-of-the-art fastener insertion machines that can revolutionize your manufacturing process. Whether you’re looking to increase production efficiency, maintain high-quality standards, or reduce labour costs, our machines can provide the solutions you need. Embrace automation and elevate your business performance with fastener insertion machines.

To read more, click here : Common Inspection Methods to Detect Failures in Hydraulic Punching Machines