Workshop Tool Calibration: Why It Matters for UAE Manufacturers

In today’s fast-paced manufacturing environment, it could be said that precision isn’t just important – it’s everything. As little as a small tolerance or measurement error can lead to wasted material, defective parts, and even time or money lost.

Because of these reasons, tool calibration is a necessity, especially in the UAE, where aerospace, automotive, and construction, for example, industries are producing accuracies every day.

For anyone operating a workshop in the UAE, small or large, it is important to be aware of the ways calibrating your tools and equipment regularly can help you improve your output and productivity. With a good set of workshop tools and a reputable workshop equipment supplier, you can run your workshop quickly, accurately, and efficiently.

What Does “Tool Calibration” Really Mean?

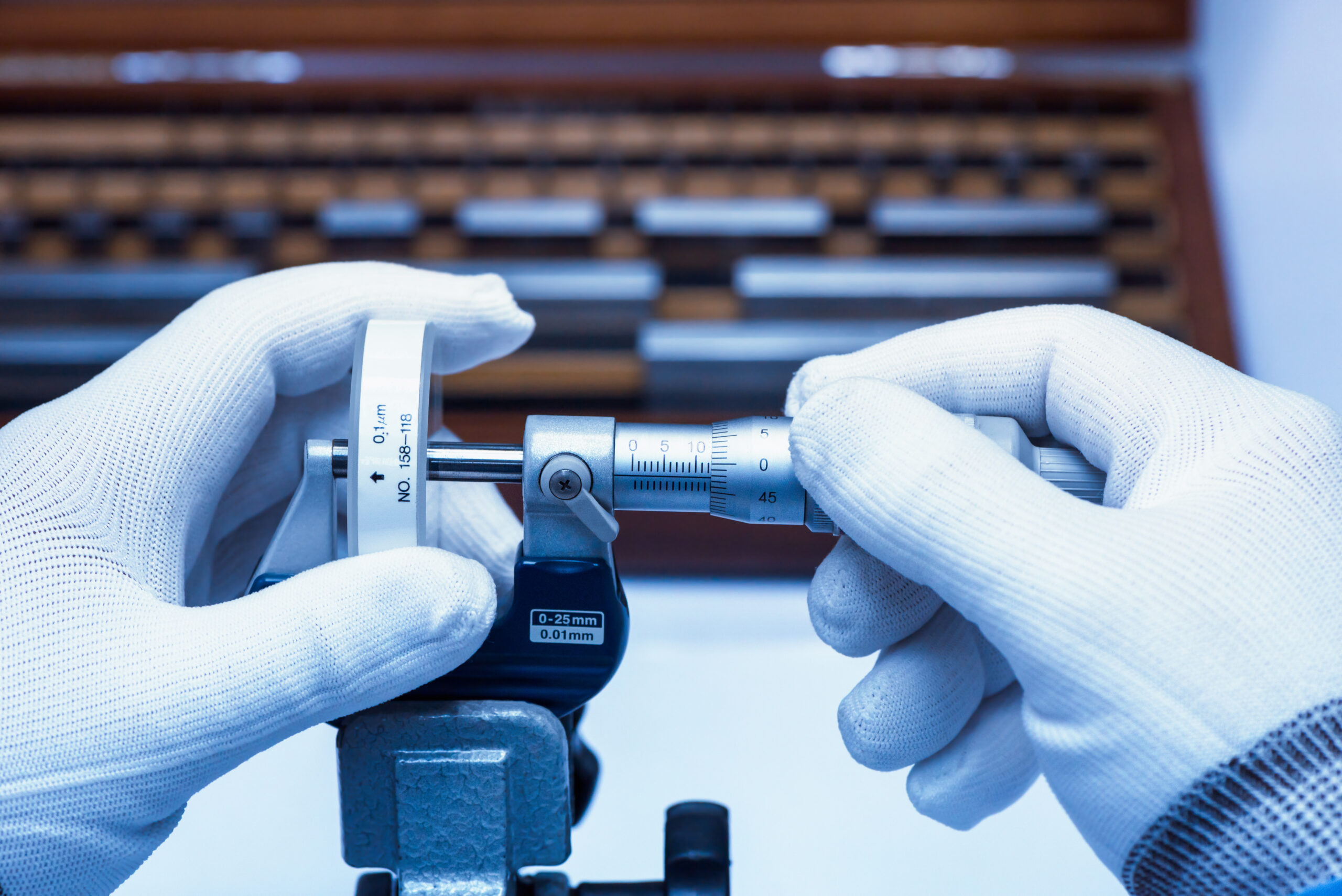

Put simply, tool calibration is the process of checking your tools to make sure they’re measuring or working as they should. It’s done by comparing a tool’s output with a known standard. If there’s a difference, adjustments are made to bring the tool back to proper working order.

This is especially important for tools that deal with precise measurements, like torque wrenches, pressure gauges, calipers, or electrical testers. Without calibration, even high-quality tools can drift over time and give you inaccurate results.

Why It’s So Important

1. You Get More Accurate Results

When your tools are calibrated, you can trust the numbers. This helps reduce errors, rework, and material waste—saving both time and money.

2. It Helps You Stay Compliant

Many industries follow strict standards, like ISO. Regular calibration helps you stay compliant and provides the necessary documentation to prove it.

3. Longer Tool Life

Calibration isn’t just about accuracy—it’s also a chance to inspect and maintain your tools. As a result, they have a reduced chance of experiencing unexpected breakdowns.

4. Less Downtime

Uncalibrated tools can cause problems on the production line. Regular checks ensure your workshop runs smoothly without interruptions.

The Increasing Demand for High-Accuracy Tools Across the UAE

With the UAE striving to become a regional manufacturing powerhouse, there’s a growing need for reliable and accurate equipment. Accuracy goes beyond being a mere buzzword—it’s the norm.

That’s why more companies are investing in high-quality workshop tools and incorporating tool calibration into their routine.

Whether you’re manufacturing car parts in Abu Dhabi or fabricating steel in Sharjah, having the right tools—and keeping them properly calibrated—gives you a competitive edge.

Top Things to Consider Before Selecting a Workshop Equipment Provider

If you want to keep your tools performing their best, start by choosing the right supplier. Here’s what a great workshop equipment provider should offer:

- Calibration Services: It’s a huge plus if your supplier offers tool calibration or partners with certified labs.

- Technical Support: A good provider won’t just sell you tools—they’ll support you after the sale too.

- Wide Tool Selection: From hand tools to precision instruments, having a one-stop shop saves time.

- UAE Market Experience: A local provider understands your industry, regulations, and the kind of tools that work best here.

How Often Should You Calibrate?

That depends on how often the tool is used, and how critical it is to your work. As a general rule:

- High-precision or frequently used tools: Check them monthly or quarterly.

- Occasional-use tools: Once a year might be enough.

It’s also smart to track calibration dates with a log or sticker system, so you never miss a check-up.

Simple Tips for Staying on Track

- Set a Regular Schedule: Don’t wait until there’s a problem. Plan your calibration.

- Educate Your Team: Ensure your staff are equipped to recognize when a tool may be out of spec.

- Label Everything: Add stickers or tags indicating when the last calibration was done and when the next one is due.

- Stick with the Experts: Let certified professionals handle your calibration—it’s worth it.

Final Thoughts

In UAE’s growing manufacturing scene, precision is everything. Proper tool calibration isn’t just about ticking boxes—it’s about making your workshop more productive, efficient, and reliable.

By partnering with a trusted workshop equipment provider and investing in top-quality workshop tools, you’re setting your business up for long-term success. You’ll reduce waste, improve accuracy, and keep your clients happy with better quality and faster turnaround.

After all, in manufacturing, it’s the small details that have the greatest impact.

To read more blogs, click here: How to Calculate Production Capacity with Different Hydraulic Punching Machine Models