Menu

Categories

- Drilling and Tool Grinding Machine

- Foam Gasket Forming Machines

- Vacuum cleaners

- Vertical lathes

- Carbide Application Equipment

- Workshop Machinery

- Tapping Machine

- Hydraulic Ironworker

- CNC Drilling and Milling machine

- Drilling and Milling machine

- Bench Drilling Machine

- Pillar type drilling machine

- CNC Lathes

- Sheet Metal Angle Notching Machine

- CNC Precision 4-high Roller Leveling Machine

- Fastener Insertion Machine

- Hydraulic Punching Machine

- Special Offer

- Radial Drilling Machines

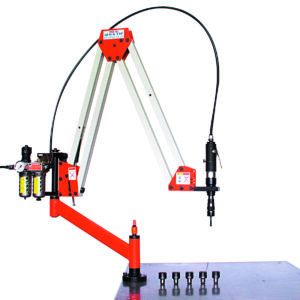

Electric Tapping Machine Type GMT

Electric Tapping Machine Type GMT is a dependable and user-friendly tool designed for accurate threading in a variety of materials.. It's perfect for industrial settings, offering strong performance with convenient features. Here’s a breakdown of what it offers:

Variable Speed Control: Lets you adjust the tapping speed to match different materials and thread sizes.

Auto-Reverse Function: Automatically reverses the spindle when the tapping process is complete, ensuring smooth operation.

Adjustable Depth Control: Allows you to set the tapping depth accurately for consistent results every time.

Ergonomic Design: Built with a user-friendly interface and comfortable handles to reduce operator fatigue and improve control.

High-Torque Motor: Provides powerful performance, making it easy to tap through tough materials.

Safety Features: Includes overload protection and an emergency stop function for safe operation.

Flexible Mounting: Can be mounted on different workbenches or stands, making it versatile for various work environments.

The Electric Tapping Machine Type GMT is a great choice for both small workshops and large factories, combining advanced features and durable construction for reliable tapping.

Product ID: GMT-Series

Powered by electricity, it uses the TRADEMAX self-developed motor and is capable of tapping sizes from M3 to M14. It works well with different thread sizes and produces less noise compared to pneumatic tapping machines. The motor speed can be easily adjusted using a knob, and additional accessories are available for multi-functional use depending on your needs.

Rockwood Machinery offers high-quality tapping machines in the UAE, designed to deliver precise and efficient threading for various industrial applications.

Enquiry

Electric Tapping Machine Type IMQ

Portable Tapping Machines Type IMQ offer advanced threading solutions designed for precision and efficiency in industrial applications. These versatile machines can easily handle a wide variety of materials, making them ideal for various work environments. Key features include:

Enquiry

- Variable Speed Control: Allows you to adjust the tapping speed for optimal performance with different materials and thread sizes.

- Auto-Reverse Function: Automatically reverses the spindle after each tap, ensuring smooth and accurate threading.

- Adjustable Depth Control: Guarantees consistent tapping depths, improving accuracy and repeatability.

- High-Torque Motor: Delivers powerful performance, making it easy to work with tough materials and challenging applications.

- Ergonomic Design: Features a user-friendly interface and comfortable handles, reducing operator fatigue and enhancing control.

- Safety Features: Equipped with overload protection and an emergency stop function for safe operation.

- Flexible Mounting Options: Can be mounted on various workbenches or stands for adaptable use across different work settings.

Electric Tapping Machine Type IMS

Electric Tapping Machine IMS-Series is designed to streamline the thread-tapping process across a wide range of materials, making it perfect for both professional workshops and DIY enthusiasts. This machine offers excellent performance and precision, delivering exceptional results for various tapping needs.

Key Features of the IMS-Series:

- Effortless Power: Powered by a high-torque electric motor, the IMS delivers reliable performance, handling tough materials and demanding applications with ease.

- Unmatched Precision: With variable speed control, operators can adjust the speed based on the material and thread size, ensuring consistent and flawless results.

- Simplified Operation: Featuring a user-friendly interface and ergonomic design, the IMS minimizes operator fatigue and provides intuitive control, enhancing workflow.

- Enhanced Safety: Equipped with overload protection and an emergency stop function, this machine prioritizes operator safety throughout the tapping process.

- Flexible Functionality: The IMS is highly versatile, accommodating various tapping needs with adjustable depth control and the ability to mount on different workbenches or stands, depending on the model.

The IMS-Series is ideal for:

- Making accurate internal threads in metal, plastic, and wood.

- Repairing damaged threads or maintaining and assembling machinery.

- Prototyping and small-scale production tasks.

Additional Features (Depending on the model):

- Auto-Reverse Function: Automatically reverses the spindle after completing each tap, ensuring smooth and efficient tapping.

- Digital Display: Offers a clear view of speed settings and tapping depth, providing enhanced control during operation.

Product ID: IMS-Series

This Electric Tapping Machine uses an induction motor and has a working range of up to 1400mm, with a tapping capacity of M3 to M24. With a quieter operation compared to pneumatic machines, the motor speed can be adjusted via the knob. The movable arm bracket ensures ease of operation, and additional accessories are available to enhance its functionality for multi-functional tapping. Ideal for workshops and industries looking for efficient tapping machines in UAE.

Enquiry

Electric Tapping Machine Type IMT

Electric tapping machines, like the Type IMT, offer a powerful and versatile solution for high-volume thread tapping operations. Designed for precision and efficiency, this industrial-grade tapping machine from [Your Company Name] enables manufacturers to achieve exceptional results in creating internal threads across a range of materials.

Key Features of the IMT:

- Powerful Electric Motor: Provides reliable performance for continuous tapping, handling materials from M3 to M24 (metric thread sizes).

- Variable Speed Control: Allows operators to adjust the tapping speed based on material and thread size, optimizing both thread quality and production times.

- Extensive Working Range: With a working range of Rmax 1900mm (maximum) to Rmin 200mm (minimum), the IMT is highly versatile, accommodating a wide variety of tapping needs.

- Durable Construction: Built with a solid machine frame and high-quality components, the IMT ensures long-lasting performance and minimal maintenance.

- Multiple Spindle Options: Choose from a range of tapping spindles (M3 – M12, M3 – M16, or M3 – M24) to suit your specific application requirements.

- User-Friendly Design: The intuitive control panel and ergonomic layout enhance operator comfort and reduce training time.

- Safety Focus: Includes overload protection and an emergency stop function for added operator safety.

Benefits of the IMT:

- Increased Production Efficiency: The high-torque motor and variable speed control facilitate faster tapping cycles compared to manual or pneumatic machines.

- Enhanced Thread Quality: Adjustable speed settings ensure consistent, accurate threads, minimizing rework and ensuring high-quality production.

- Reduced Operator Fatigue: The ergonomic design reduces strain, enhancing productivity during long shifts.

- Versatility for Various Applications: The IMT's broad working range and multiple spindle options make it suitable for diverse industries, including automotive, aerospace, and general metalworking.

- Cost-Effective Operation: The electric motor operates more cost-effectively compared to pneumatic tapping machines.

Ideal for:

- High-volume production lines in industries like automotive, aerospace, and general metalworking.

- Applications needing consistent and high-quality internal threads.

- Workshops and factories aiming to improve tapping efficiency and reduce production times.

The IMT Electric Tapping Machine is a reliable solution for tapping machines in UAE, offering enhanced versatility and lower operating costs compared to pneumatic alternatives.

Product ID: IMT-Series

Powered by electricity, this machine utilizes the TRADEMAX self-developed induction motor and offers a working range of up to 1900mm with a tapping capacity of M3 to M24. The machine operates more quietly than pneumatic versions and features an adjustable motor speed control. The movable arm design simplifies operation and offers greater convenience. Additional tapping attachments and accessories can be purchased for multi-functional use based on working conditions.

Enquiry

Type AQ-08,12 Pneumatic Tapping Machi...

Pneumatic Tapping Devices by Rockwood Workshop Machines are efficient and user-friendly solutions designed for creating clean and precise internal threads across a wide range of materials. These pneumatic tapping machines are ideal for workshops, assembly lines, and on-site applications in the UAE, offering portability and ease of use for various tapping needs.

Key Features of the AQ-08,12:

- Efficient Pneumatic Operation: Powered by compressed air, the AQ-08,12 ensures smooth tapping without requiring an electrical connection, providing high efficiency in any environment.

- Compact and Portable Design: Lightweight and easy to maneuver, the machine is perfect for tight workspaces or on-site use, making it a versatile choice for different settings.

- Flexible Working Range: With a working range of up to 950mm and a minimum reach of 100mm, the AQ-08,12 offers flexibility for different tapping tasks.

- Adjustable Tapping Capacity: Accommodates a wide range of tap sizes from M2 to M8, making it suitable for a variety of applications.

- Simplified Operation: Features a user-friendly control panel and an easy setup process, ensuring quick operation and minimal training time for operators.

- Durable Construction: Built with high-quality materials, the AQ-08,12 is designed for long-lasting performance and low maintenance.

- Enhanced Versatility: Comes with both a stretch arm and a slanted arm, offering operators flexibility for accessing various work areas with ease.

Benefits of the AQ-08,12:

- Improved Efficiency: The pneumatic operation increases tapping speed, providing higher productivity compared to manual methods.

- Cost-Effective Operation: Air-powered tapping reduces the need for electrical connections, which can lower operating costs.

- Enhanced Accuracy: Its compact, maneuverable design allows for precise control, leading to clean and consistent thread results.

- Reduced Operator Fatigue: The lightweight, ergonomic design ensures operator comfort and reduces fatigue during extended use.

- Wide Range of Applications: Ideal for industries like automotive, furniture manufacturing, and electrical assembly lines.

The AQ-08,12 Pneumatic Tapping Machine is an invaluable tool for:

- Workshops looking for an efficient and portable tapping solution.

- Assembly lines aiming to improve tapping efficiency and reduce production time.

- Field service technicians needing a reliable tapping solution for on-site work.

Product ID: AQ-08,12

Powered by air pressure, this tapping machine provides a working range of up to 950mm and supports tapping capacities from M2 to M12. It’s perfect for creating inner hole threads in different sizes. The simple, movable arm design makes it easy to operate, and with additional accessories, it can be adapted for multi-functional tapping.

Enquiry

Type AS-08,12/II Pneumatic Tapping Ma...

The Type AS-08,12/II Pneumatic Tapping Machine is a powerful and flexible tool designed for internal thread tapping in workshops and industrial settings. It offers great control and performance, making it perfect for a variety of materials and thread sizes.

Key Features of the AS-08,12/II:

- High-Torque Pneumatic Motor: Provides strong, consistent power for tapping through materials like metals, plastics, and some hardwoods.

- Extended Working Range: With a reach of up to 1400mm, this machine allows easy access to different workpieces.

- Adjustable Tapping Capacity: Can handle tap sizes from M2 to M12, making it suitable for many projects.

- Movable Arm Design: Offers easy maneuverability and control, even in tight spaces, for precise tapping.

- Multiple Arm Options: Choose between a standard arm or a slanted arm (depending on availability) for the best tapping angle.

- User-Friendly Controls: Simple control panel design makes setup quick and easy, improving workflow.

- Safety Features: Includes overload protection and an emergency stop for operator safety.

- Optional Accessories: You can add tapping attachments, safety clutches, and table mounting columns to improve functionality (availability may vary).

Benefits of the AS-08,12/II:

- Powerful Performance: The strong pneumatic motor ensures smooth tapping, even in tough materials.

- Improved Accuracy: The movable arm design allows precise control, resulting in clean, consistent threads.

- Better Productivity: The long reach and efficient operation save time and streamline tapping processes.

- Comfortable Operation: The movable arm and easy controls reduce operator strain, making it more comfortable to use for long periods.

- Versatility: The AS-08,12/II is perfect for a wide range of industries, including automotive, metal fabrication, furniture manufacturing, and electrical assembly lines.

The Type AS-08,12/II Pneumatic Tapping Machine is well-suited for:

- Workshops and factories needing a powerful, reliable tapping solution.

- Projects requiring precise thread tapping in various materials.

- Industries looking to boost tapping efficiency and productivity.

Product ID: AQ-08,12

This machine operates using air pressure, offering a working range of up to 950mm and a tapping capacity from M2 to M12. It is easy to assemble, and the movable arm design makes it simple to operate. Depending on your needs, you can also purchase additional accessories for more versatile tapping.

Enquiry

Type AT-08,12/I Pneumatic Tapping Mac...

The Type AT-08,12/I Pneumatic Tapping Machine is a powerful and easy-to-use tool for creating clean, precise internal threads in workshops and production lines. Powered by air, it offers excellent reach and tapping capacity, making it perfect for a variety of tasks.

Key Features of the AT-08,12/I:

Enquiry

- Efficient Pneumatic Operation: The machine is powered by compressed air, providing smooth tapping without the need for electricity.

- Wide Working Range: With a reach of up to 1600mm, it can access even deep workpieces, offering great flexibility.

- Versatile Tapping Capacity: The machine can handle tap sizes from M2 to M12, making it suitable for many different projects.

- Movable Arm Design: The movable arm gives operators better control and easy movement for precise tapping, even in tight spaces.

- User-Friendly Controls: The simple control panel makes operation quick and easy, saving setup time.

- Safety Features: Includes overload protection and an emergency stop function to keep operators safe.

- Easy Reach: The long working range allows tapping of deep workpieces or hard-to-reach areas without needing to reposition.

- Cost-Effective: Using compressed air reduces the need for an electrical connection, which can lower operating costs.

- Accurate Tapping: The movable arm ensures precise control, creating clean and consistent threads every time.

- Boosted Productivity: Efficient operation and a long reach help reduce setup time and improve overall productivity.

- Versatile Use: Ideal for many industries, such as automotive repair, furniture manufacturing, and electrical assembly lines.

- Workshops and factories needing a long-reach tapping solution.

- Production lines aiming to improve tapping efficiency for deeper workpieces.

- Tasks requiring precise threading in various materials.

Type AT-08,12/II Pneumatic Tapping Ma...

The Type AT-08,12/II Pneumatic Tapping Machine is a powerful tool designed to handle tough internal thread tapping tasks in workshops and industrial settings. Powered by air, it offers a wide working range and excellent tapping capacity, making it perfect for projects that require both precision and deep access.

Key Features of the AT-08,12/II:

- Efficient Pneumatic Operation: The air-powered motor ensures smooth and easy tapping, even with tough materials.

- Wide Working Range: With a reach of up to 1900mm, the AT-08,12/II reduces the need to reposition the machine, saving time.

- Versatile Tapping Capacity: It can handle a range of tap sizes, from M2 to M12, making it suitable for various projects.

- Easy Control and Maneuvering: The movable arm design gives operators full control, especially when working in tight spaces or with deep workpieces.

- User-Friendly: The simple control panel makes operation easy, even for users with less experience.

- Safety Features: Includes overload protection and an emergency stop function for added safety.

- Optional Accessories: Enhance its capabilities with additional tapping attachments and safety clutches (availability may vary).

Benefits of the AT-08,12/II:

- Efficient for Deep Workpieces: The long working range allows you to tap deep workpieces or those with limited access, offering more flexibility.

- Boosts Productivity: The powerful operation and long reach reduce setup time, making the tapping process faster and more efficient.

- High Accuracy: The movable arm design ensures precise control, resulting in clean, consistent threads.

- Less Operator Fatigue: The ergonomic design helps reduce strain, allowing for more comfortable use during extended periods.

- Wide Application: Perfect for industries such as automotive, metal fabrication, furniture manufacturing, and electrical assembly lines.

The Type AT-08,12/II Pneumatic Tapping Machine is perfect for:

- Workshops and production facilities that need a powerful tapping solution with long reach.

- Projects that require precise threads in deep or hard-to-reach areas.

- Industries looking to improve tapping efficiency and productivity, especially in high-volume operations.

Product ID: AT-08,12/II

This air-powered machine has a working range of up to 1900mm and can tap sizes from M2 to M12. It's easy to assemble, and the movable arm design ensures simple and convenient operation. Additional accessories can be purchased for multi-functional tapping based on your needs.

Enquiry

Type HM-22,32,42,50 – Hydraulic...

The Type HM-22,32,42,50 Hydraulic Tapping Machine offers unparalleled power and precision for demanding thread tapping applications in industrial environments. This heavy-duty machine utilizes hydraulic operation to deliver exceptional performance and efficiency, making it ideal for high-volume production lines and workshops.

Key Features of the HM-22,32,42,50:

Robust Hydraulic Operation: The hydraulic system guarantees consistent and powerful tapping, tackling even the toughest materials with ease.

Extensive Working Range: With a working range of up to 1600mm (maximum reach), the HM-22,32,42,50 offers exceptional flexibility for diverse tapping needs.

Unmatched Tapping Capacity: This machine boasts a wide tapping capacity range, handling taps from M3 to M50 (metric thread sizes), making it suitable for a broad spectrum of projects.

Movable Arm Design: The included movable arm provides operators with optimal control and maneuverability for precise tapping, even in tight spaces.

User-Friendly Controls: The intuitive control panel simplifies operation and minimizes setup time, allowing for efficient workflow integration.

Safety Focus: Operator safety is prioritized with overload protection and an emergency stop function.

Standard Accessories: The HM-22,32,42,50 comes equipped with a hydraulic tapping spindle, stretch arm, slanted arm, table mounting column, and a selection of safety clutch tapping adapters (specific number may vary).

Benefits of the HM-22,32,42,50:

Enhanced Production Efficiency: The powerful hydraulic operation and extensive working range ensure faster tapping cycles, leading to significant productivity improvements.

Effortless Power for Demanding Applications: The hydraulic system delivers consistent torque, making it ideal for tapping challenging materials such as thick metals and high-strength alloys.

Exceptional Thread Quality: The precise control and rigidity of the machine contribute to creating clean and consistent threads, minimizing rework and optimizing product quality.

Reduced Operator Fatigue: The ergonomic design and easy operation minimize operator strain during extended use.

Versatility for Diverse Industries: The HM-22,32,42,50 caters to a wide range of applications in automotive, aerospace, general metalworking, and other demanding industries.

The Type HM-22,32,42,50 Hydraulic Tapping Machine is ideal for:

High-volume production lines seeking maximum efficiency and performance.

Workshops requiring a robust and reliable tapping solution for challenging materials.

Industries prioritizing consistent high-quality thread creation.

Enquiry

- Product ID: HM-22,32,42,50Mainly relies on hydraulic to operate, working range is up to 1600mm, tapping capacity is M3~M50. Can be used for the production of inner hole threads of different sizes. The stand is designed as a movable arm, providing the user with an easy and convenient way to operate. Include work cart. According to the working conditions, accessories can also be purchased to achieve multi-functional tapping.

Type HMT-22,32,42,50 – Hydrauli...

Hydraulic Tapping Machines Type HMT-22, 32, 42, 50 offer exceptional efficiency and control for demanding thread tapping applications in industrial settings. These robust machines use a hydraulic system to provide unmatched power and precision, making them ideal for high-volume production lines and workshops. Key features include:

- Powerful Hydraulic Operation: The efficient hydraulic system ensures smooth and consistent tapping, handling a wide range of materials with ease.

- Extended Working Range: With a reach of up to 1900mm, these tapping machines offer excellent flexibility for various tapping needs.

- Versatile Tapping Capacity: Accommodates taps from M3 to M50 (metric thread sizes), covering a broad range of project requirements.

- Movable Arm Design: The movable arm improves control and maneuverability when tapping in tight or hard-to-reach spaces.

- User-Friendly Controls: An intuitive control panel simplifies operation, reducing setup time and boosting workflow efficiency.

- Safety Features: Overload protection and an emergency stop function ensure operator safety during use.

- Integrated Work Cart: The included work cart with a T-slotted platform provides a stable workspace for material handling and workpiece positioning.

- Standard Accessories: Includes a hydraulic tapping spindle, stretch arm, slanted arm, table mounting column, and safety clutch tapping adapters (specific number may vary).

Benefits of the HMT-22, 32, 42, 50:

- Enhanced Productivity: The hydraulic operation and wide working range reduce tapping cycle times, improving production efficiency.

- Effortless Power for Tough Materials: The hydraulic system ensures consistent torque, making it ideal for tapping tough materials like thick metals and high-strength alloys.

- Precise Thread Creation: The machine’s control and rigidity help produce clean, consistent threads, minimizing rework and enhancing product quality.

- Operator Comfort: The movable arm design and easy-to-use controls reduce operator fatigue during extended use.

- Wide Applications: These tapping machines are suitable for automotive, aerospace, metalworking, and other industries requiring high-performance tapping solutions.

The HMT-22, 32, 42, 50 Hydraulic Tapping Machines are ideal for:

- High-volume production lines that demand top performance and efficiency.

- Workshops needing a robust and reliable tapping solution for tough materials.

- Industries that prioritize consistent, high-quality thread creation.

Product ID: HMT-22, 32, 42, 50

These machines primarily rely on hydraulic operation. The work cart features a T-slot platform, and the working range extends up to 1900mm with a tapping capacity from M3 to M50. The movable arm design ensures easy operation, and the included work cart provides stability. Depending on the work conditions, additional accessories can be purchased to enhance functionality. For businesses seeking reliable **tapping machines in UAE**, the HMT series offers an efficient and versatile solution for demanding applications.

Enquiry

Product Categories

- Bench Drilling Machine

- Carbide Application Equipment

- CNC Drilling and Milling machine

- CNC Lathes

- CNC Precision 4-high Roller Leveling Machine

- Drilling and Milling machine

- Drilling and Tool Grinding Machine

- Fastener Insertion Machine

- Foam Gasket Forming Machines

- Hydraulic Ironworker

- Hydraulic press

- Hydraulic Punching Machine

- Pillar type drilling machine

- Radial Drilling Machines

- Sheet Metal Angle Notching Machine

- Tapping Machine

- Vacuum cleaners

- Vertical lathes