Troubleshooting Common Problems in Ironworker Machines

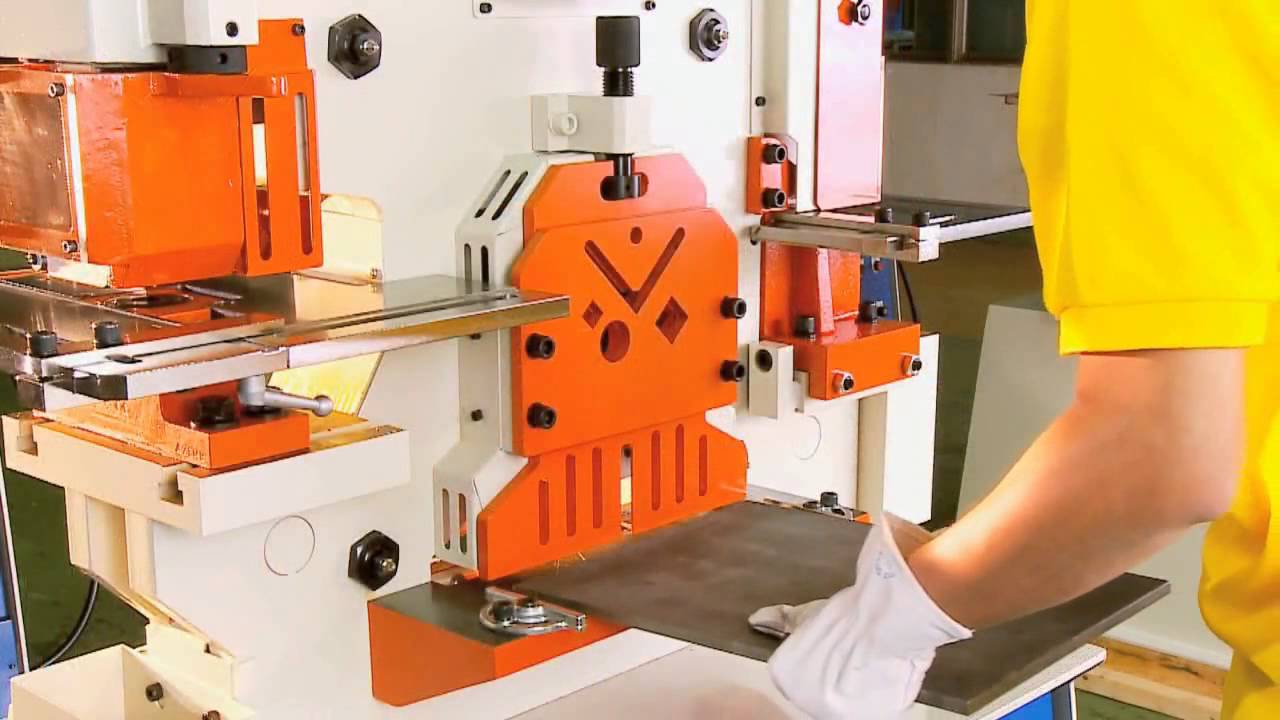

Ironworker machines are important workshop tools utilized in a variety of industries, including manufacturing and construction. Revolutionize your workshop with these multifunctional machines that combine shearing, punching, and notching capabilities for unmatched productivity. However, ironworker machines in UAE can encounter problems that disrupt operations like any complex machinery. Understanding and solving problems is crucial for getting the best results and avoiding expensive delays. This article will look at typical difficulties with ironworker equipment and offer practical ways to keep your workshop tools in top shape.

1. Hydraulic System Failures

Problem:

One of the most common problems with ironworker machines is hydraulic system failure. This is capable of malfunctioning the hydraulic system may cause the machine to operate more slowly, cause the moving elements to move irregularly, or even cause the system to fail.

Troubleshooting Steps:

1. Check Hydraulic Fluid Levels: Make sure there’s enough hydraulic fluid in the machine. Insufficient fluid levels can prevent the machine from generating adequate pressure for proper operation. It may move unpredictably or slowly as a result.

2. Check for Leaks: Look for leaks around the seals, hoses, and fittings. If you find any, it could mean the machine is losing pressure, which can make it work poorly.

3. Examine Hydraulic Pump: If the pump is broken, it won’t be able to create enough pressure. Listen for strange sounds or vibrations coming from the pump. If you hear anything unusual, it might need to be fixed or replaced.

4. Replace Filters: The machine may become less efficient due to slowed fluid flow caused by blocked filters. Regularly changing the filters will keep the machine operating properly.

2. Electrical Problems

Problem:

Electrical issues can cause ironworker machines to malfunction, including problems with starting, inconsistent power supply, or control system failures.

Troubleshooting Steps:

1. Inspect Wiring and Connections: Check for corrosion, looseness, or damage on all electrical connections. In addition to replacing broken wires, tighten any slack connections.

2. Test Control Panels: Use a multimeter to check the control panels and verify that they receive and distribute power correctly.

3. Check Fuses and Circuit Breakers: A tripped circuit breaker or blown fuse will result in power loss to the machine. If any circuit breakers have tripped, reset them and replace any blown fuses.

4. Examine Motors and Relays: Faulty motors or relays can cause operational issues. Inspect all components and replace them if needed.

3. Mechanical Wear and Tear

Problem:

Over time, ironworking machines wear out just like any other machine. The mechanical parts of ironworker machines can wear out over time, failing or reducing performance.

Troubleshooting Steps:

1. Regular Lubrication: In order to minimize wear and friction, make sure that all of the moving parts are properly lubricated. Refer to the manufacturer’s recommendations on the type of lubricators to use and follow the schedule between lubrications.

2. Inspect for Wear: Check for wear on important parts such as dies, punches, and blades on a regular basis and replace them as needed.

3. Alignment Checks: Alignment of the moving components should be checked regularly, misaligned parts will result in uneven cuts and damage to the machine.

4. Tighten Fasteners: Fasteners may become less secure with time. All the nuts and screws should be checked and tightened on a regular basis.

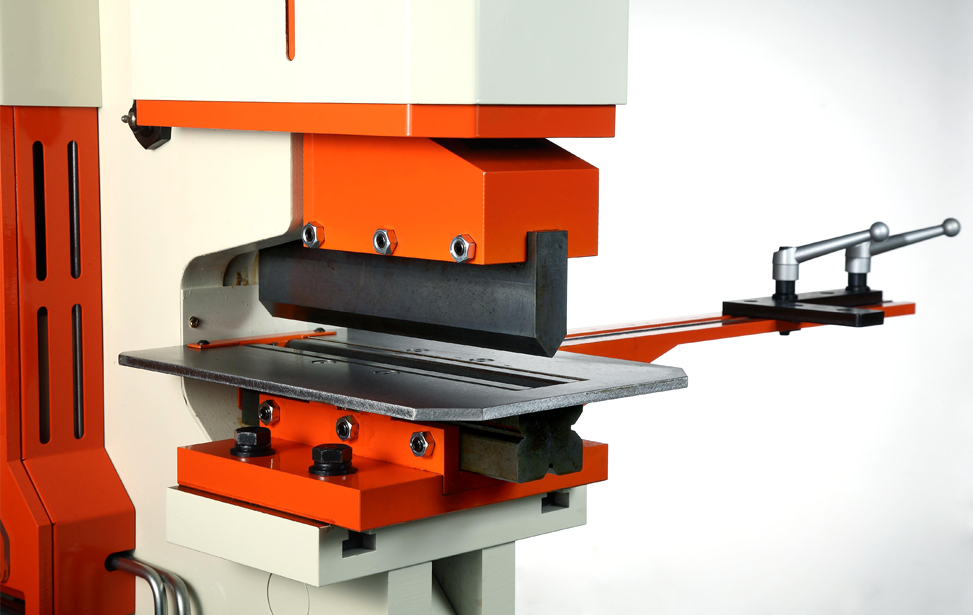

4. Punch and Die Misalignment

Problem:

If punches and dies are not aligned properly might result in uneven cuts, increased wear, and possible ironworker machine damage.

Troubleshooting Steps:

1. Check Alignment Regularly: To accurately align punches and dies, utilize alignment tools and make necessary adjustments.

2. Inspect Punch and Die Holders: Worn or damaged holders can cause misalignment. Replace any worn-out parts.

3. Adjust Guide Rails: While the machine is operating, guide rails help maintain alignment. Always make sure they’re properly greased and adjusted.

4. Use Correct Tooling: Ensure you are using the correct punches and dies for the material and thickness being processed.

5. Inconsistent Cutting and Punching Quality

Problem:

Various factors can cause inconsistent cutting or punching quality. These factors include using dull blades, incorrect settings, and difficulties with the material being cut or punched.

Troubleshooting Steps:

1. Sharpen or Replace Blades and Punches: Always keep blades and punches sharp, dull blades and punches will result in bad cuts and hurt the machine.

2. Adjust Cutting Settings: Verify that your machine is configured correctly for the type of material you are using. The results will be poor if the parameters are incorrect.

3. Check Material Quality: Low-quality or unsuitable materials can cause issues. Ensure the material is appropriate for the machine and the specific task.

4. Calibrate Machine: Calibrate the unit on an ongoing basis to make sure it is functioning within the set parameters.

6. Operator Errors in Ironworker Machines

Problem:

Human mistake is a common cause of issues with ironworker machines. Improper operation can result in accidents, machine damage, and poor performance.

Troubleshooting Steps:

1. Training and Education: Make sure everyone who operates the machine is properly trained and knows how to use it safely.

2. Clear Instructions: Provide clear and concise operating instructions and safety guidelines.

3. Regular Practice: Encourage operators to practice regularly and stay updated with the latest operational techniques.

4. Supervision and Monitoring: To improve quality control, we should implement oversight procedures that allow us to identify and correct staff mistakes as they happen.

Maintaining the efficiency and performance of ironworker machines in the UAE is important for any workshop involved in heavy-duty industrial tasks. By understanding and fixing common problems, operators can keep their machines running smoothly, which means less downtime and more work getting done. Keeping your machines well-maintained, training your operators properly, and following the manufacturer’s guidelines are essential for getting the best performance out of your ironworker machines and other workshop tools in the UAE. You can satisfy the needs of the expanding industrial sector in the area and maintain the smooth and effective operation of your business by being proactive and paying attention.

Read also : Preventing Industrial Vacuum Cleaner Breakdowns in Warehouses